Automotive Compressor Clutch Replacement: Step-by-Step Guide for Reliable A/C Performance

When and Why Clutch Replacement Becomes Necessary

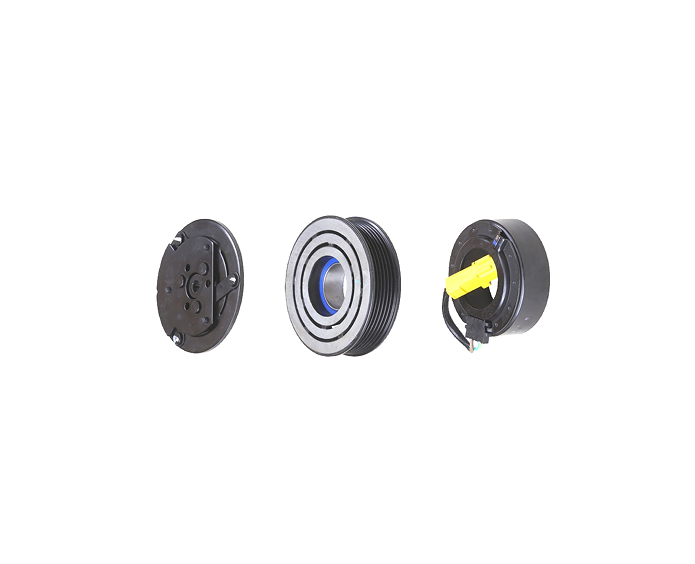

The automotive compressor clutch enables the A/C compressor to engage and disengage as needed, balancing engine load and cooling demand. Over time, constant cycling under heat and torque causes wear in the coil, pulley, bearing, and friction plate.

Typical signs that replacement is needed include:

-

Unusual squealing or grinding noises from the compressor front.

-

A/C cooling failure even with proper refrigerant levels.

-

Burnt smell or visible scoring on the clutch plate.

-

Coil resistance deviation beyond ±10% of rated value.

Ignoring these symptoms can lead to full compressor seizure or belt damage. Replacing the clutch early prevents costlier system failures.

Preparation and Safety Precautions

Before replacement, technicians should ensure proper working conditions and observe key safety steps:

-

Disconnect the battery and depressurize the A/C system if required.

-

Verify the compressor model and voltage (12V or 24V) to match the correct KASEN clutch kit.

-

Prepare a torque wrench, puller tool, and gap gauge (0.4–0.6 mm).

-

Inspect the drive belt, tensioner, and compressor mounting bolts for wear or misalignment.

KASEN supplies clutch kits with all necessary components—coil, pulley, hub, bearing, snap rings, and spacers—pre-balanced and ready for direct installation.

Step-by-Step Replacement Procedure

Proper installation ensures correct torque transfer and magnetic engagement.

| Step | Procedure | Technical Note |

|---|---|---|

| 1 | Remove the A/C drive belt. | Mark rotation direction before removal. |

| 2 | Detach the clutch plate (hub) using a puller tool. | Avoid prying with screwdrivers to prevent shaft damage. |

| 3 | Remove snap ring and slide off pulley and bearing assembly. | Inspect shaft and housing for scoring. |

| 4 | Disconnect and remove old coil assembly. | Measure old coil resistance for diagnostic comparison. |

| 5 | Install new Kasen coil and align connector orientation. | Secure evenly; avoid overtightening. |

| 6 | Press-fit new pulley and install bearing snap ring. | Verify free rotation without side play. |

| 7 | Mount clutch plate and adjust air gap (0.4–0.6 mm). | Use feeler gauge at three positions for accuracy. |

| 8 | Reinstall belt, reconnect wiring, and test clutch engagement. | Observe smooth operation and silent activation. |

Following this sequence minimizes mechanical stress and ensures magnetic response consistency.

Common Mistakes and How to Avoid Them

Even experienced technicians may encounter issues during clutch replacement.

KASEN highlights several key points to ensure proper installation:

-

Incorrect air gap leads to slipping or continuous engagement.

-

Non-balanced pulleys cause vibration at high RPMs.

-

Contaminated bearing seats result in noise and premature wear.

-

Aftermarket coil mismatch triggers voltage drop or overheating.

Using an OEM-quality KASEN clutch assembly eliminates these issues by providing factory-calibrated balance, precise tolerances, and standardized connectors.

Technical Specifications for Reliable Operation

Every KASEN clutch assembly adheres to strict electrical and mechanical parameters:

| Specification | Value | Description |

|---|---|---|

| Rated Voltage | 12V / 24V DC | Supports passenger and commercial vehicles |

| Coil Resistance | 3.8–4.2 Ω (12V) | ±1.5% tolerance |

| Magnetic Pull | 350–480 N | Verified under 13.5 V |

| Engagement Time | <0.05 s | Fast magnetic response |

| Bearing Noise | ≤58 dB | Under 6,000 RPM rotation |

| Torque Endurance | 300,000+ cycles | Long-term reliability |

These specifications guarantee smooth compressor activation, low noise, and efficient energy transfer over the system’s lifespan.

Post-Replacement Testing and Calibration

Once installed, the clutch assembly must be tested under running conditions:

-

Engage and disengage the A/C system at idle and 2,000 RPM to verify smooth response.

-

Monitor clutch temperature rise (should remain ≤45 °C after 10 minutes).

-

Check belt tension and pulley alignment once more after operation.

-

Re-measure air gap after 24 hours of operation to ensure stability.

KASEN recommends maintaining a voltage supply of 13.5 ± 0.5 V for optimal coil performance.

Why KASEN OEM Assemblies Ensure Long-Term Reliability

KASEN clutch assemblies are designed for plug-and-play replacement—engineered and pre-tested to match OEM standards in torque, magnetic field, and dimensional accuracy.

Advantages include:

-

Factory-calibrated balance and clearance, eliminating on-site adjustments.

-

Thermally stable insulation preventing coil degradation.

-

Anti-corrosion coatings extending service life in humid climates.

-

Full traceability for global distributor and workshop support.

This ensures every replacement not only restores performance but improves long-term compressor durability.

Partner with KASEN for Professional Replacement Solutions

With decades of experience in compressor component engineering, KASEN provides a complete range of clutch assemblies, coils, and replacement kits that simplify A/C repair and maintenance.

Each assembly is manufactured under ISO/TS 16949 standards, ensuring precision, consistency, and safety in every replacement operation.

To request replacement guides, technical support, or OEM cooperation, visit the KASEN homepage or contact the service team via the contact page.

FAQ: Automotive Compressor Clutch Replacement

Q1. Can I replace the clutch without removing the compressor?

Yes, in many cases. If there’s no internal compressor failure, KASEN’s pre-assembled kits can be installed directly on the vehicle.

Q2. How long does clutch replacement take?

With a pre-calibrated Kasen kit, installation typically takes 1–1.5 hours using standard tools.

Q3. How do I identify the correct clutch model?

Check the compressor label or part number; Kasen provides a cross-reference table for Denso, Sanden, Delphi, and Valeo systems.

Q4. Should I replace the coil and bearing together?

Yes, to ensure balanced performance and prevent future noise or resistance variation.