A/C Compressor Clutch Failure Diagnosis and Preventive Maintenance: Keeping Cooling Systems Reliable

A/C Compressor Clutch Failure Diagnosis and Preventive Maintenance: Keeping Cooling Systems Reliable

Why Early Diagnosis Prevents Costly Compressor Damage

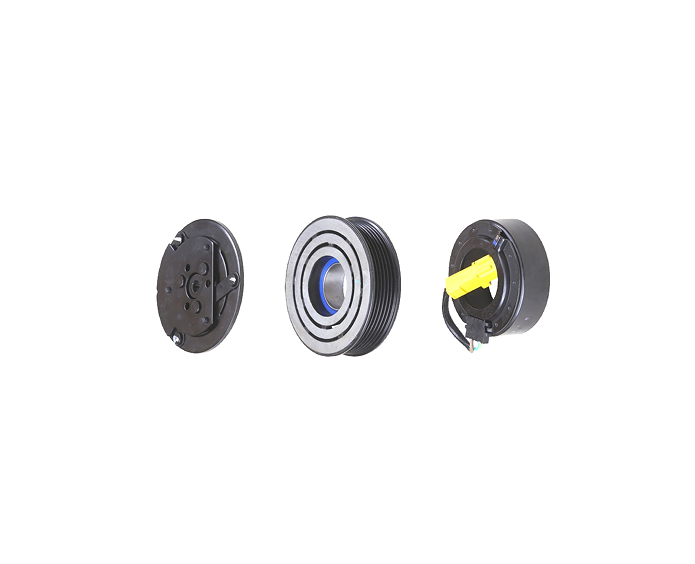

The A/C compressor clutch acts as the critical bridge between the engine’s mechanical power and the air-conditioning system. When it begins to fail, even minor performance deviations—like delayed engagement or noise—can escalate into full compressor breakdowns.

Identifying early symptoms helps technicians prevent downstream failures such as bearing seizure, coil burnout, or belt snapping. Kasen emphasizes diagnostic precision and preventive maintenance as the key to ensuring long-term reliability and efficiency in A/C systems.

Recognizing Early Warning Signs of Clutch Failure

Every failure starts with subtle physical or electrical indicators.

Technicians should look out for:

-

Audible Symptoms: Grinding, rattling, or metallic clicking during engagement.

-

Visual Indicators: Discoloration on clutch plate or pulley surface.

-

Electrical Deviations: Coil resistance outside OEM tolerance (±10% of rated 3.8–4.2 Ω).

-

Performance Drop: Delayed clutch activation or compressor not cycling at idle.

-

Overheating: Burnt smell near the clutch hub, indicating friction overload.

KASEN clutches are engineered with stable coil resistance and high-temperature insulation, minimizing the likelihood of such early degradation.

Mechanical vs. Electrical Failure Modes

Understanding whether a failure is mechanical or electrical allows for targeted maintenance.

| Failure Type | Typical Cause | Observable Symptom | Recommended Action |

|---|---|---|---|

| Bearing Wear | Contamination, lubrication loss | Squealing noise at idle | Replace clutch bearing and pulley |

| Coil Burnout | Voltage surge, overheating | No magnetic engagement | Test circuit voltage, replace coil |

| Plate Glazing | Excessive slippage | Reduced torque transfer | Clean or replace friction plate |

| Pulley Misalignment | Belt tension error | Belt vibration or wear | Realign pulley and recheck belt tension |

| Air Gap Deviation | Shim loss, improper torque | Weak magnetic pull | Re-shim and recalibrate air gap |

Kasen’s OEM-grade assemblies use corrosion-protected bearings, balanced pulleys, and reinforced insulation materials to withstand these stress factors.

Essential Diagnostic Tools and Procedures

Professional diagnosis requires more than visual inspection.

KASEN recommends the following workflow:

-

Resistance Test:

-

Disconnect the coil connector and measure resistance using a multimeter.

-

Expected range: 3.8–4.2 Ω at 20°C (12V system).

-

Deviation indicates internal coil damage or insulation breakdown.

-

-

Current Draw Test:

-

Activate the clutch circuit and observe current flow.

-

Normal operating range: 3.5–4.0 A.

-

Abnormal spikes suggest shorted windings.

-

-

Air Gap Measurement:

-

Use a 0.5 mm feeler gauge; check at three points for uniform clearance.

-

-

Noise & Vibration Analysis:

-

Utilize a stethoscope or vibration sensor during clutch cycling.

-

Irregular rhythm or metallic knocking implies bearing failure.

-

-

Visual Alignment Inspection:

-

Check pulley wobble (<0.2 mm runout).

-

Misalignment leads to accelerated belt wear and coil heating.

-

By standardizing these steps, workshops can minimize replacement errors and extend system life.

Preventive Maintenance Schedule

Preventive care ensures the clutch maintains consistent magnetic strength and smooth torque transfer over time.

| Mileage Interval | Maintenance Action | KASEN OEM Recommendation |

|---|---|---|

| Every 30,000 km | Visual inspection of pulley & clutch plate | Clean surfaces with non-abrasive solvent |

| Every 60,000 km | Coil resistance & air gap measurement | Adjust with OEM shim kit if deviation found |

| Every 80,000–100,000 km | Replace clutch bearing | Use KASEN pre-lubricated bearings |

| Every 120,000 km | Full clutch assembly inspection | Replace worn parts as preventive action |

With Kasen’s pre-calibrated clutch kits, replacement and maintenance align seamlessly with these OEM intervals.

Thermal and Electrical Stress Reduction Techniques

One major cause of clutch failure is thermal overload—especially in congested engine bays or tropical climates.

KASEN clutches integrate several countermeasures:

-

High-temp epoxy coating (Class H insulation) preventing coil degradation up to 180°C.

-

Optimized magnetic path design reducing energy loss and heat buildup.

-

Ventilated pulley structure enhancing cooling airflow during high RPMs.

-

Voltage stabilization tolerance ±0.5 V, avoiding magnetic overexcitation.

These design details collectively extend component lifespan and improve long-term compressor performance.

Data Logging and Predictive Maintenance for Fleets

Fleet operators and OEM service centers increasingly rely on predictive diagnostics.

By logging clutch activation frequency, current draw, and coil temperature, maintenance teams can anticipate service needs before breakdowns occur.

KASEN supports this trend by offering standardized electrical signatures across all clutch models—allowing ECUs to track wear rates and alert operators when performance thresholds are exceeded.

Such integration reduces unscheduled maintenance downtime and enhances reliability for commercial fleets.

Partner with KASEN for Reliable Cooling System Longevity

A properly maintained A/C compressor clutch ensures quiet, efficient, and dependable cooling performance for years.

KASEN’s OEM-grade components combine magnetic precision, heat stability, and wear resistance—helping technicians reduce replacement frequency and workshop returns.

For detailed maintenance manuals, OEM supply inquiries, or customized diagnostic kits, visit the KASEN homepage or contact our engineering team via the contact page.

FAQ: A/C Compressor Clutch Diagnosis

Q1. What is the most common cause of clutch failure?

Bearing wear and coil overheating due to poor ventilation or excessive belt tension.

Q2. Can I repair a burnt coil?

No, the coil should be replaced with a new Kasen OEM unit to ensure insulation safety.

Q3. Why does the clutch slip even after replacement?

Air gap misadjustment or contaminated friction surfaces; recalibration is necessary.

Q4. How can predictive maintenance improve reliability?

By monitoring clutch current and engagement frequency, operators can detect early deterioration and prevent sudden failure.