A/C Compressor Clutch Innovation: Advanced Materials and System Efficiency for Modern Automotive Cooling

From Mechanical Control to Smart Energy Management

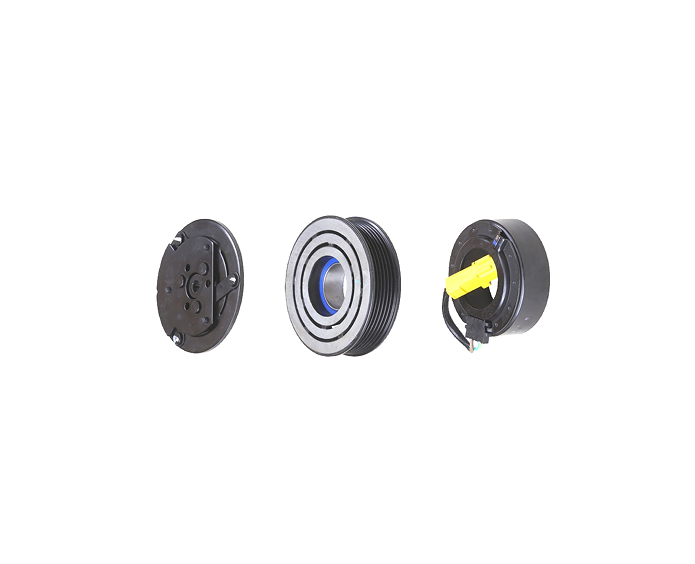

The A/C compressor clutch has evolved from a simple mechanical switch into a precision energy management device. In today’s vehicles—especially hybrid and compact-engine models—every watt of efficiency matters.

By synchronizing compressor load with real-time cooling demand, the clutch enables fuel savings, reduces engine drag, and stabilizes cabin temperature.

KASEN’s engineering philosophy focuses on electromagnetic precision, thermal optimization, and mechanical symmetry, ensuring the clutch remains both efficient and durable even under high-frequency operation.

High-Efficiency Magnetic Systems for Faster Engagement

Traditional clutch coils often waste current due to magnetic flux leakage.

KASEN overcomes this by employing low-resistance copper windings and magnetic circuit optimization, improving conversion efficiency between current and mechanical pull force.

Key Engineering Features:

-

Flux Density Optimization: Improved magnetic concentration around core region, minimizing stray loss.

-

Energy Efficiency: 10–15% lower current draw under identical torque load.

-

Rapid Activation: Engagement within 0.04 seconds, reducing system lag.

-

Voltage Stability: Coil maintains ±1.5% resistance variation under continuous duty.

The result is precise clutch activation with minimal delay—critical for stop-start systems and hybrid cooling applications.

Thermal Management Through Multi-Layer Design

The A/C clutch endures extreme temperature fluctuations—often switching between −30 °C winter starts and 180 °C under-hood heat.

KASEN addresses these challenges through a multi-layer heat control system:

-

Thermally conductive epoxy encapsulation dissipates heat evenly from coil windings.

-

Ventilated pulley grooves promote airflow during high-speed rotation.

-

Graphite-infused clutch friction layer reduces temperature spikes during engagement.

-

Heat-stable bearing lubricants sustain viscosity under long idle conditions.

This system reduces coil temperature rise by up to 20%, extending insulation life and preventing magnetic decay common in aftermarket designs.

Material Innovation: Strength Meets Stability

Material science lies at the heart of Kasen’s product reliability.

Each A/C compressor clutch assembly utilizes high-carbon steel, precision aluminum alloys, and friction-coated composite surfaces, selected through finite element analysis (FEA) and fatigue testing.

| Component | Material | Enhancement |

|---|---|---|

| Coil Core | Laminated steel | Reduced eddy current and energy loss |

| Pulley | High-carbon alloy | Dynamic balancing and impact resistance |

| Friction Plate | Composite graphite coating | Smooth torque transfer and reduced glazing |

| Bearing | Chromium steel with synthetic grease | Lower noise and longer lifespan |

| Connector Housing | Glass-fiber reinforced nylon | Heat-resistant and electrically insulated |

The synergy between these materials ensures stable mechanical strength while minimizing weight—a key factor in modern vehicle energy optimization.

Dynamic Balancing and NVH Optimization

Vibration control (NVH: Noise, Vibration, Harshness) defines how comfortable and quiet an air-conditioning system feels.

KASEN’s production employs 6,000 RPM dynamic balancing to reduce radial runout below 0.02 mm, preventing belt resonance and audible vibration.

Additional innovations include:

-

Laser-trimmed friction plates for uniform torque application.

-

Double-sealed bearings isolating vibration frequencies.

-

Low-friction pulley coatings minimizing start-up squeal.

-

Comprehensive acoustic testing (<58 dB in-cabin level under compressor load).

These measures deliver whisper-quiet performance, making Kasen clutches ideal for premium passenger vehicles and EV-based HVAC systems.

Smart Diagnostics and Predictive Maintenance

Modern A/C systems integrate electronic control units (ECUs) capable of monitoring clutch performance.

KASEN’s OEM clutches are designed to support these intelligent systems via stable resistance signatures and temperature consistency curves, allowing predictive diagnostics.

Technicians and manufacturers benefit from:

-

Current feedback mapping for coil health monitoring.

-

On-board detection of delayed engagement caused by wear or voltage loss.

-

Data consistency for automated calibration across ECU-controlled compressors.

This data-driven approach extends component lifespan and reduces unscheduled service downtime.

Sustainability Through Manufacturing Efficiency

KASEN’s manufacturing facilities adopt a closed-loop sustainability model:

-

Recycled steel and copper in coil and pulley production.

-

Lead-free epoxy coatings compliant with RoHS/REACH.

-

Automated energy monitoring to minimize factory carbon footprint.

-

Batch traceability system ensuring full lifecycle accountability.

Each clutch not only performs efficiently but is also manufactured with environmental responsibility—supporting OEMs’ sustainability goals.

Partner with KASEN for the Next Generation of A/C Compressor Clutches

With expertise spanning magnetic design, heat management, and precision mechanics, KASEN provides OEM partners with the next evolution of compressor clutch technology.

Each unit is engineered for energy efficiency, system compatibility, and long-term endurance, supported by ISO/TS 16949-certified production.

For detailed specifications, technical consultation, or OEM collaboration, visit the KASEN homepage or contact our engineering team via the contact page.

FAQ: A/C Compressor Clutch Innovation

Q1. What makes KASEN’s clutch more efficient than traditional designs?

Optimized magnetic flux paths and high-purity copper reduce electrical loss while improving torque response.

Q2. How does the clutch maintain performance under heat?

Multi-layer thermal control and heat-dissipating epoxy stabilize coil temperature even under prolonged engagement.

Q3. Can the clutch integrate with hybrid or start-stop systems?

Yes. KASEN’s clutches are compatible with ECU-controlled activation, offering rapid response for energy-efficient vehicles.

Q4. What testing validates Kasen’s OEM-grade reliability?

Each clutch undergoes 300,000+ engagement tests, dynamic balancing, and high-temperature endurance verification.