A/C Compressor Clutch Manufacturing Process: Precision, Automation, and Quality Assurance

Turning Engineering Blueprints into Functional Reliability

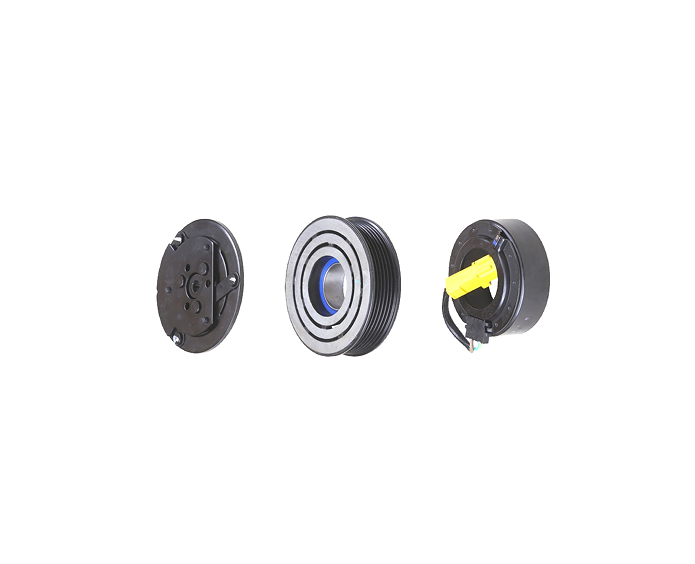

Behind every A/C compressor clutch lies a combination of magnetic precision, mechanical accuracy, and rigorous testing.

KASEN’s production facilities integrate advanced CNC technology, automated coil winding, and dynamic balancing systems to achieve the consistency demanded by global automotive OEMs.

From raw material selection to final torque validation, every process is controlled within micrometer-level tolerance—ensuring that each clutch performs flawlessly under real-world conditions.

1. Material Preparation and Component Forming

The process begins with selecting certified alloy steels and copper conductors, sourced from ISO-approved suppliers.

-

Pulley & Hub: Machined from high-carbon structural steel to withstand torsional load.

-

Coil Core: Made from laminated silicon steel sheets, reducing magnetic flux loss.

-

Friction Plate: Formed using composite materials for balanced grip and wear resistance.

All steel components undergo induction hardening (up to 40 HRC) to enhance fatigue strength and dimensional stability.

Before machining, each blank is inspected for chemical uniformity via spectral analysis, guaranteeing metallurgical integrity throughout the batch.

2. CNC Machining and Dimensional Precision

KASEN’s clutch housings, hubs, and pulleys are manufactured using 5-axis CNC machining centers to achieve geometric accuracy within ±0.01 mm.

Key operations include:

-

Turning and milling with CNC lathes for concentricity.

-

Drilling and grooving for belt compatibility.

-

Surface grinding to control flatness and reduce vibration.

Each machined component passes through a coordinate measuring machine (CMM) to ensure dimensional precision.

This guarantees uniform air gaps, balanced friction surfaces, and consistent torque transfer characteristics.

3. Automated Coil Winding and Epoxy Sealing

The electromagnetic coil is the heart of the compressor clutch—it dictates engagement timing and magnetic strength.

KASEN uses fully automated winding lines with tension-controlled copper wire feed systems to maintain coil resistance within 1% of specification.

| Parameter | KASEN Standard | Tolerance |

|---|---|---|

| Wire Gauge | 0.65 mm enamelled copper | ±0.01 mm |

| Coil Resistance (12V) | 3.9 Ω | ±0.05 Ω |

| Insulation Grade | Class H (180°C) | – |

| Voltage Endurance | 1500V / 1 min | – |

After winding, the coil is sealed with thermally conductive epoxy resin that improves heat dissipation and moisture resistance, ensuring long-term durability even in tropical environments.

4. Assembly and Air Gap Calibration

Assembly requires perfect alignment between coil, pulley, and clutch plate.

Each clutch is assembled using hydraulic alignment jigs that fix the magnetic and rotational axis in position.

-

The air gap (0.4–0.6 mm) is calibrated using precision shims.

-

The pulley bearing is press-fitted with uniform preload to minimize friction.

-

Torque fasteners are applied under controlled tightening force to maintain axial symmetry.

Post-assembly inspection verifies runout ≤0.02 mm, ensuring smooth operation and low NVH (Noise, Vibration, Harshness).

5. Dynamic Balancing and NVH Optimization

Dynamic balance directly affects the clutch’s life and the compressor’s stability.

KASEN utilizes high-speed balancing machines operating at up to 10,000 RPM, simulating real-world engine speeds.

Every pulley is corrected to achieve balance grade G2.5 per ISO 1940, eliminating vibration that can cause belt wear or bearing failure.

Each clutch then undergoes acoustic testing in a semi-anechoic chamber to ensure engagement noise remains below 58 dB.

6. Performance Testing and Endurance Validation

Before leaving the factory, 100% of Kasen clutches are tested for:

-

Magnetic response time (<0.05 sec)

-

Torque capacity (25–40 N·m depending on model)

-

Thermal stability after 300,000 engagement cycles

-

Electrical safety via dielectric and resistance tests

-

Salt spray corrosion resistance up to 500 hours

For OEM batches, random samples undergo lifecycle and environmental stress testing, including temperature cycling between −30°C and +180°C.

This ensures that Kasen clutches maintain consistent performance across all climate zones.

7. Packaging and Traceability

Each unit is serialized with a laser-engraved batch code, linking it to material certificates, process logs, and inspection data.

The packaging is designed to protect magnetic and friction surfaces during transit, using anti-static and moisture-resistant materials.

KASEN’s ERP system maintains full traceability, ensuring every part can be tracked from raw steel coil to finished product delivery.

8. Quality Assurance Philosophy

KASEN follows a zero-defect manufacturing philosophy supported by:

-

ISO/TS 16949 quality management certification.

-

SPC (Statistical Process Control) on every production line.

-

Automated defect detection through optical sensors.

-

Continuous improvement loops driven by customer feedback and field data.

Every clutch shipped reflects KASEN’s commitment to reliability, precision, and measurable engineering excellence.

Partner with KASEN for OEM-Grade Production Reliability

KASEN’s manufacturing ecosystem transforms precision engineering into repeatable quality.

Each A/C compressor clutch undergoes hundreds of checks and balances, ensuring durability, consistency, and compatibility across vehicle platforms.

To explore technical documentation, custom production capabilities, or OEM cooperation opportunities, visit the KASEN homepage or reach our team via the contact page.

FAQ: A/C Compressor Clutch Manufacturing

Q1. What machining tolerance does Kasen maintain on pulley alignment?

All pulleys are machined and verified to within ±0.01 mm concentricity using CNC calibration.

Q2. Are Kasen clutches compatible with major compressor brands?

Yes. Kasen clutches are designed to fit Sanden, Denso, Delphi, and Valeo compressors with OEM-level precision.

Q3. How does Kasen ensure coil consistency across production batches?

Fully automated winding and resistance monitoring maintain ±1% resistance deviation.

Q4. What quality certifications does Kasen hold?

Kasen is certified under ISO/TS 16949 and ISO 14001, with 100% final inspection and batch traceability.