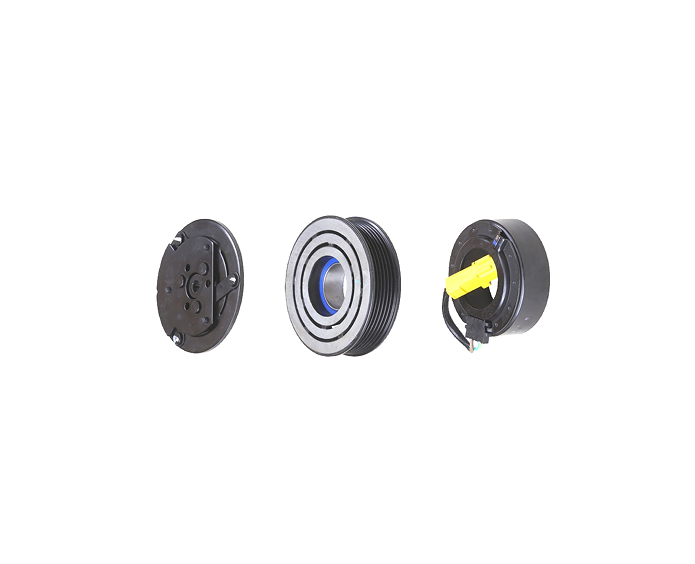

Material Engineering Behind the A/C Compressor Clutch: Durability Through Metallurgy and Surface Innovation

Why Material Science Defines Clutch Longevity

An A/C compressor clutch operates in one of the most punishing environments in a vehicle—high temperature, high speed, and repetitive engagement cycles.

Each start-stop sequence subjects the clutch to intense thermal gradients, magnetic loads, and torsional stress. Without precise material control, fatigue cracks, wear marks, and demagnetization can occur within months.

KASEN addresses this challenge by engineering the clutch from the inside out—optimizing alloys, friction compounds, coatings, and lubricants for stable performance across millions of cycles.

High-Strength Steel Alloys for Structural Stability

The foundation of the clutch lies in its steel core assembly, which transmits torque from the pulley to the compressor shaft.

KASEN uses high-carbon, chromium-molybdenum steels (equivalent to AISI 4140) that are:

-

Heat-treated to 35–40 HRC for torsional fatigue resistance.

-

Tempered for toughness under cyclic stress.

-

Shot-peened to eliminate microcracks and enhance fatigue life by 30%.

The steels are processed through controlled atmosphere furnaces, ensuring uniform hardness and eliminating oxidation during heat treatment.

This metallurgical precision ensures that even under 6,000 RPM continuous rotation, hub deformation remains below 0.01 mm—maintaining clutch engagement consistency and magnetic alignment.

Advanced Friction Surface Technology

The friction plate is where the clutch’s performance is truly determined—it must grip instantly yet resist glazing and wear.

KASEN’s proprietary graphite-infused composite coating provides optimal friction behavior across temperature ranges.

| Property | Standard Material | KASEN Composite |

|---|---|---|

| Friction Coefficient (μ) | 0.28–0.32 | 0.35–0.42 |

| Thermal Stability | Up to 120°C | Up to 180°C |

| Wear Rate | High under high RPM | 40% lower |

| Engagement Smoothness | Moderate | Excellent |

The coating uses a hybrid matrix of resin-bonded graphite and ceramic microparticles, applied via electrostatic spray and baked at 250°C.

The result is a surface that maintains consistent torque delivery even under continuous stop-start operation, minimizing slip-induced heat buildup.

Corrosion and Oxidation Resistance

In tropical or coastal markets, corrosion is one of the most common causes of compressor clutch failure.

To combat this, KASEN applies a three-stage protection process:

-

Phosphate pretreatment for adhesion and surface sealing.

-

Electro-deposition coating (EDC) with 25 μm thickness, providing uniform coverage.

-

Epoxy overcoat resistant to 500-hour salt spray tests per ASTM B117.

This ensures that the clutch remains structurally intact even after prolonged exposure to humidity, road salt, or temperature cycling—crucial for vehicles operating in Asia, the Middle East, and coastal Europe.

Thermal Endurance and Heat Flow Management

During continuous cycling, the clutch coil can reach temperatures above 160°C, while the friction plate may spike to 200°C during heavy load.

To prevent failure under such thermal stress, KASEN employs a multi-material thermal control system:

-

Epoxy-encapsulated copper windings to prevent insulation breakdown.

-

Pulley ventilation slots for improved airflow.

-

Thermally conductive bearing grease for stable viscosity under heat.

-

Low-expansion materials in the hub to maintain magnetic gap precision.

Finite Element Analysis (FEA) simulations are used to model heat flow, enabling engineers to predict thermal deformation before production.

Dynamic Wear Testing and Lifecycle Verification

Durability is not theoretical—it’s validated through rigorous endurance testing.

Each clutch undergoes multi-phase validation:

-

Engagement cycle test: 300,000 operations under 13.5 V and 6,000 RPM.

-

Thermal shock test: −30°C to +180°C, 500 cycles.

-

Salt spray and humidity test: 96-hour cycles to simulate real-world exposure.

-

NVH analysis: Ensures vibration levels remain below 58 dB during operation.

Post-test microscopy confirms minimal wear on contact surfaces and stable torque output.

These data-driven methods allow Kasen to maintain OEM reliability benchmarks even in aftermarket applications.

Environmentally Responsible Material Choices

KASEN’s material strategy balances performance with sustainability:

-

Lead-free epoxy coatings compliant with RoHS and REACH standards.

-

Recyclable copper and aluminum content in coils and housings.

-

Low-emission heat treatment furnaces with waste gas recovery.

-

ISO 14001 certified production line ensuring eco-responsible material management.

Through these initiatives, Kasen delivers not only durability but also environmental compliance—an increasingly crucial factor in global OEM sourcing.

Partner with KASEN for Material-Driven Reliability

By combining advanced metallurgy, coating technology, and thermal control, KASEN builds A/C compressor clutches that outperform conventional components in durability and energy stability.

Every part—from the steel core to the final friction surface—is engineered for measurable longevity and consistent performance.

For detailed specifications, OEM supply collaboration, or technical consultation, visit the KASEN homepage or contact our engineering team via the contact page.

FAQ: A/C Compressor Clutch Material and Durability

Q1. What causes most clutch wear in long-term use?

Thermal stress, oxidation, and micro-slip on friction surfaces are leading factors—Kasen’s composite coating mitigates all three.

Q2. How does Kasen improve corrosion resistance?

Through a phosphate + EDC + epoxy triple-coating system tested under 500-hour salt spray exposure.

Q3. Can these materials handle high-frequency cycling in hybrid vehicles?

Yes. The materials are tested to sustain over 300,000 magnetic engagement cycles with minimal wear.

Q4. Are Kasen clutches recyclable?

Yes. Steel, copper, and aluminum components are fully recyclable, and coatings comply with global environmental standards.