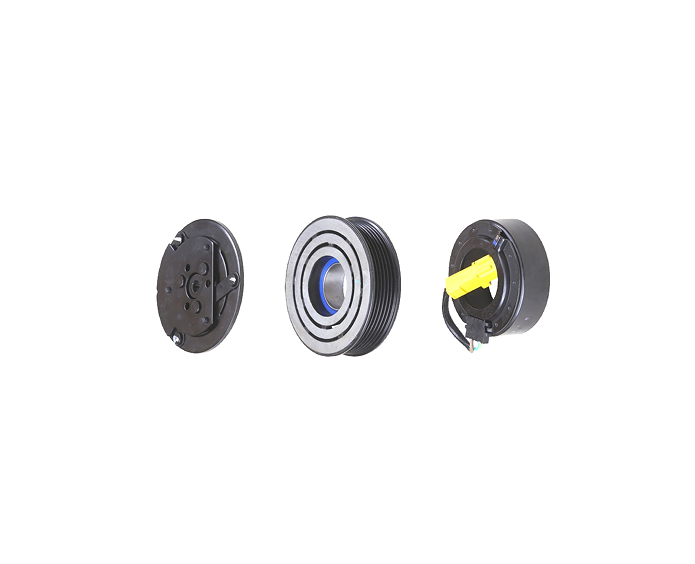

OEM Customization for A/C Compressor Clutch: Tailored Engineering for Global Vehicle Platforms

The Need for Custom Engineering in Modern Vehicle A/C Systems

No two vehicle platforms share identical cooling requirements.

Factors such as engine layout, climate conditions, operating voltage, and compressor design all determine how an A/C compressor clutch must perform.

KASEN partners with automotive OEMs and system integrators to develop customized clutch assemblies that meet precise performance targets while remaining cost-efficient for mass production.

From compact sedans to heavy-duty commercial vehicles, Kasen’s R&D team tailors every design parameter—from coil resistance to bearing type—to ensure exact compatibility and long-term reliability.

Platform-Based Engineering Approach

KASEN’s engineering workflow starts with understanding the vehicle platform’s thermal load and duty cycle.

For example:

-

Compact cars require rapid magnetic response and low noise.

-

SUVs need higher torque and thermal endurance under heavy A/C use.

-

Commercial fleets demand wear-resistant bearings and anti-corrosion coatings for long service life.

Using data-driven design tools, Kasen engineers simulate magnetic flux, torque output, and engagement dynamics before prototype production.

This ensures each clutch meets both system-level performance and energy efficiency requirements.

Customizable Design Parameters

Every Kasen A/C compressor clutch can be configured across multiple dimensions to suit customer specifications:

| Category | Customizable Features | Typical Range / Options |

|---|---|---|

| Coil System | Voltage rating, resistance, wire gauge, insulation class | 12V / 24V / 48V; 3.5–4.2 Ω; Class H |

| Torque Output | Engagement torque for different compressors | 25–45 N·m |

| Pulley Design | Belt type, groove count, diameter | PK, V, PV series; Ø90–130 mm |

| Bearing Type | Load capacity, lubrication spec | Standard / Heavy-duty sealed bearings |

| Connector Type | Electrical interface compatibility | AMP, Sumitomo, Delphi plugs |

| Surface Coating | Corrosion resistance, color options | E-coat, Zn-Ni plating, epoxy finish |

Each variable undergoes tolerance analysis and verification testing to maintain consistency across global manufacturing batches.

Electrical and Magnetic Adaptation

Different OEM electrical systems require specific coil resistance and current draw characteristics.

KASEN designs custom electromagnetic coils optimized for each platform’s voltage stability and activation pattern.

Key engineering adaptations include:

-

Low-current coil variants for hybrid and stop-start systems.

-

High-resistance coils for vehicles operating in hot climates to prevent overheating.

-

EMI-shielded versions minimizing signal interference in ECU-heavy environments.

-

Fast-response magnetic designs (<0.04 s activation delay) for real-time A/C control modules.

Through this customization, Kasen ensures reliable engagement and minimal voltage fluctuation, even under fluctuating alternator outputs.

Mechanical Compatibility with Multiple Compressor Brands

KASEN’s clutches are designed to fit a wide range of compressor families, including Denso, Sanden, Valeo, and Delphi.

Each clutch undergoes mounting interface mapping to match bolt patterns, hub profiles, and pulley alignment.

By integrating modular mechanical interfaces, Kasen enables:

-

Seamless replacement across multiple vehicle lines.

-

Simplified inventory management for OEMs.

-

Easy adaptation for regional suppliers or aftermarket networks.

This flexibility allows Kasen to serve both Tier 1 compressor manufacturers and vehicle assemblers across Asia, Europe, and the Americas.

Environmental and Regional Adaptations

Climate and environment dramatically affect clutch design.

KASEN provides tailored variants for diverse regional needs:

-

Tropical markets (Southeast Asia, Middle East): Enhanced heat resistance, anti-rust coatings.

-

Cold regions (Europe, North America): Low-temperature lubrication and flexible polymer insulation.

-

Dust-prone environments (Africa, South America): Sealed bearings and reinforced epoxy layers.

These adaptations ensure consistent performance from −40°C to +180°C, maintaining torque stability and noise control under all weather conditions.

Prototyping, Validation, and OEM Integration

KASEN employs a closed-loop OEM collaboration process, including digital simulation, rapid prototyping, and field testing.

-

3D CAD and FEA modeling to predict torque, magnetic flux, and vibration response.

-

Prototype fabrication within 15–20 days for design validation.

-

Dynamic and thermal testing on OEM compressors for real-condition evaluation.

-

Statistical process control (SPC) ensuring repeatability across large production runs.

Once validated, each clutch is assigned a unique OEM part number and integrated into the customer’s supply chain through Kasen’s ERP-based logistics system.

Flexible Manufacturing for Global Demands

KASEN’s manufacturing system supports both high-volume OEM supply and low-volume customization.

-

Automated coil winding lines with resistance verification.

-

Multi-station CNC assembly cells for precise alignment.

-

Batch-specific traceability with laser-engraved serial codes.

-

Lean manufacturing principles minimizing waste and energy consumption.

This flexible structure allows Kasen to adapt quickly to changing OEM requirements or new compressor models without compromising lead time or quality.

Partner with KASEN for Tailored A/C Clutch Solutions

KASEN’s OEM customization capability transforms the A/C compressor clutch from a standardized component into a vehicle-specific performance solution.

By combining electromagnetic engineering, material science, and global production experience, Kasen ensures every clutch meets the precise standards of modern automotive systems.

For technical collaboration, custom design requests, or OEM integration projects, visit the KASEN homepage or reach our team via the contact page.

FAQ: OEM Customization for A/C Compressor Clutch

Q1. How long does Kasen take to deliver a custom clutch prototype?

Typically 2–3 weeks from design confirmation, depending on coil and pulley specifications.

Q2. Can Kasen design clutches for 24V or 48V systems?

Yes, Kasen offers coil designs for 12V, 24V, and 48V applications used in hybrid and commercial vehicles.

Q3. What if an OEM requires a specific connector type?

Kasen supports a wide range of connector standards including AMP, Delphi, and Sumitomo.

Q4. Does Kasen provide testing data and certification?

All custom models come with full performance test reports, dimensional drawings, and validation documentation.