Automotive Compressor Clutch Adjustment: Precision Air Gap and Torque Calibration for Reliable A/C Operation

Why Precision Adjustment Matters

In an automotive air-conditioning system, even a 0.1 mm deviation in clutch air gap can alter engagement timing, create noise, or reduce cooling efficiency. The compressor clutch adjustment process ensures that magnetic, mechanical, and rotational forces remain balanced for optimal system performance.

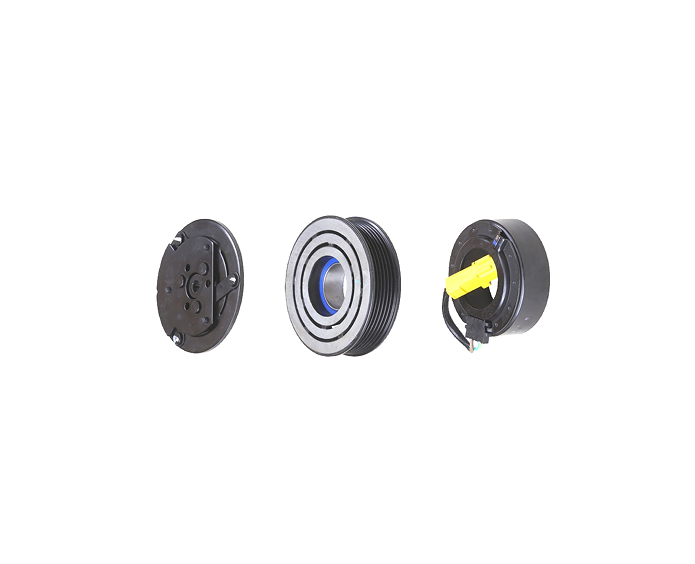

KASEN’s OEM-grade clutch assemblies are pre-calibrated, but understanding proper adjustment principles is essential for technicians performing installations, replacements, or maintenance checks.

Understanding the Air Gap and Its Role

The air gap is the small clearance between the clutch plate and the pulley surface when the system is disengaged.

It directly determines:

-

Magnetic response time – too wide, and engagement is delayed.

-

Wear and friction – too narrow, and constant contact causes heat and wear.

-

Power efficiency – correct gap minimizes drag losses.

KASEN recommends maintaining an air gap between 0.4–0.6 mm, depending on compressor type. This range provides the ideal balance between fast engagement and low mechanical stress.

Step-by-Step Air Gap Adjustment Process

Precision adjustment requires methodical steps and calibrated tools.

| Step | Procedure | Technical Note |

|---|---|---|

| 1 | Disconnect the battery and remove the A/C belt. | Safety first—prevent accidental clutch activation. |

| 2 | Check coil voltage and resistance. | Ensure the electrical system meets 12V or 24V OEM specs. |

| 3 | Measure the current air gap with a feeler gauge. | Measure at three equally spaced points. |

| 4 | Remove the clutch plate and add or remove shims. | Use OEM spacer set; each shim typically equals 0.1 mm. |

| 5 | Reinstall clutch plate and torque to spec. | Standard torque: 12–15 N·m (light-duty), 18–20 N·m (heavy-duty). |

| 6 | Recheck air gap and adjust as needed. | Target 0.4–0.6 mm tolerance. |

| 7 | Reconnect battery and test engagement. | Engagement should occur instantly and silently. |

Accurate measurement and gradual adjustment ensure the clutch engages magnetically without drag or slippage.

Torque Calibration and Friction Surface Control

Once the air gap is set, verifying torque output ensures that the clutch can handle compressor load under real-world conditions.

KASEN clutch assemblies are dynamically tested to achieve consistent torque transfer (25–40 N·m) without overloading the belt system.

During manual calibration:

-

Avoid overtightening the center bolt—it affects plate alignment.

-

Use a non-contact tachometer to measure compressor response speed.

-

Check that clutch torque engagement remains stable across temperature variations from −30 °C to +120 °C.

KASEN’s precision-ground clutch plates maintain uniform friction coefficient (μ = 0.35–0.45), reducing engagement shock and improving NVH (Noise, Vibration, Harshness) performance.

Common Misadjustments and Their Consequences

Improper calibration can cause cascading system failures.

| Misadjustment Type | Symptom | Consequence |

|---|---|---|

| Air gap too wide (>0.8 mm) | Delayed engagement, weak cooling | Coil overheating, incomplete clutch pull-in |

| Air gap too narrow (<0.3 mm) | Constant contact, noise | Friction surface wear, heat buildup |

| Uneven plate alignment | Pulsation, vibration | Bearing damage, belt noise |

| Incorrect torque preload | Slippage under load | Reduced compressor life |

OEM calibration eliminates these risks, ensuring the clutch operates smoothly for hundreds of thousands of cycles.

Testing and Verification Standards

KASEN’s production lines apply the same standards used by global automotive manufacturers. Each clutch assembly is verified for:

-

Air gap consistency at three contact points.

-

Magnetic field uniformity using Hall-effect sensors.

-

Torque endurance tested over 300,000 engagement cycles.

-

Noise and vibration testing (<58 dB at 6,000 RPM).

-

Thermal cycling between −30 °C and +180 °C.

Technicians performing field adjustments can use these same parameters to confirm compliance with OEM tolerances.

KASEN’s OEM Advantage: Pre-Calibrated Assemblies

All KASEN A/C compressor clutches are factory-calibrated and balanced during production.

Key advantages:

-

No field adjustment required for new units.

-

Consistent engagement torque and response time.

-

Reduced installation error and technician labor.

-

Lower warranty risk through stable long-term performance.

For replacement and maintenance, KASEN also provides pre-shimmed clutch kits, ensuring correct air gap and alignment out of the box.

Partner with KASEN for Precision A/C Components

Precision adjustment defines the reliability of every air-conditioning compressor system. KASEN’s pre-calibrated clutch assemblies and kits combine magnetic precision, mechanical balance, and thermal endurance—supporting global OEMs and service professionals alike.

For calibration guides, engineering support, or OEM collaboration, visit the KASEN homepage or contact the service team via the contact page.

FAQ: Automotive Compressor Clutch Adjustment

Q1. How often should clutch air gap be checked?

Every 60,000–80,000 km, or when engagement noise or slippage appears.

Q2. Can the air gap be adjusted without removing the compressor?

Yes, but precise measurement and OEM shims are required for in-vehicle calibration.

Q3. What happens if air gap exceeds OEM tolerance?

The clutch may fail to engage properly, causing weak cooling and coil burnout.

Q4. Does Kasen provide adjustment tools or shims?

Yes. Kasen supplies OEM shim kits and installation tools for professional service centers.