Coil Design and Performance Testing in KASEN Automotive Air Conditioner Clutch Systems

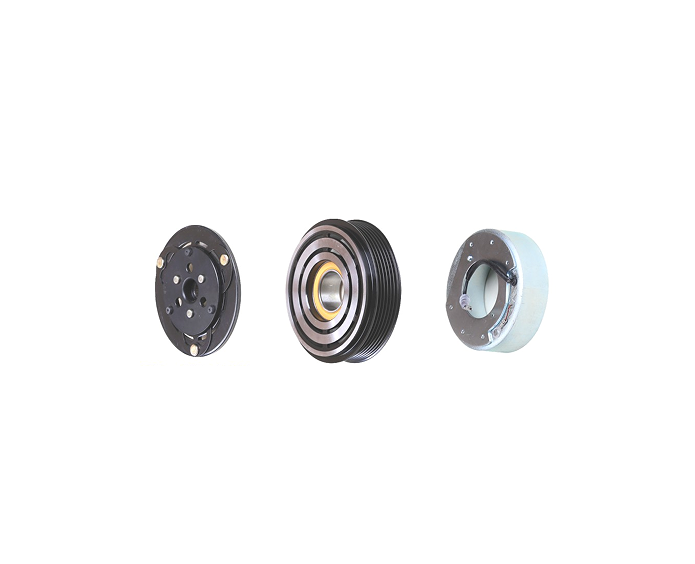

Engineering the Magnetic Core of Performance

Within every automotive air conditioner clutch, the coil is the unseen powerhouse.

It transforms electrical current into a precise magnetic field, engaging the compressor clutch with exact timing and torque control.

At KASEN, this component is not off-the-shelf—it’s custom-engineered through an iterative design process balancing electrical efficiency, thermal endurance, and manufacturability.

1. Material Selection: Balancing Conductivity and Durability

The foundation of a reliable coil lies in the choice of materials.

KASEN uses oxygen-free high-conductivity copper (OFHC) wire coated with dual-layer heat-resistant enamel, rated for continuous operation at 180°C.

| Property | KASEN Coil | Generic Coil | Performance Impact |

|---|---|---|---|

| Wire Type | OFHC Copper | Copper-Aluminum blend | Higher conductivity |

| Insulation Class | Class H (180°C) | Class F (155°C) | Better thermal stability |

| Enamel Layer | Dual (polyamide + polyesterimide) | Single | Improved moisture protection |

| Winding Density | 88–92% | 75–80% | Higher magnetic flux efficiency |

Every coil batch is verified by eddy-current conductivity testing to ensure consistency before winding.

2. Advanced Winding Process and Thermal Optimization

The coil winding process determines both magnetic symmetry and heat dispersion.

KASEN employs CNC-controlled automatic winders with laser-tension feedback to maintain uniform layer spacing and prevent micro-cracks in the enamel coating.

Design Highlights:

-

Precision winding at ±0.02 mm tension variance.

-

Core encapsulation with high-temperature epoxy to enhance dielectric strength.

-

Integrated heat-sink structure between windings and housing, improving cooling efficiency by 20%.

The result: coils that maintain consistent resistance and magnetic output even under fluctuating ambient temperatures.

3. Magnetic Pull Force Calibration

Magnetic strength defines clutch reliability.

Each automotive air conditioner clutch coil undergoes magnetic pull force measurement under simulated load.

| Parameter | KASEN Standard | Industry Average |

|---|---|---|

| Pull Force at 12V | ≥ 450 N | 340–380 N |

| Response Time | ≤ 0.04 s | 0.08 s typical |

| Residual Magnetism | < 5% | 10–15% |

| Energy Conversion Efficiency | > 85% | 70–75% |

Pull-force testers record magnetic rise curves in real time, automatically rejecting coils that deviate beyond ±2% tolerance.

Insight: A higher magnetic efficiency not only ensures secure engagement but also reduces compressor drag, lowering overall engine load and fuel consumption.

4. Thermal Performance and Endurance Testing

KASEN’s laboratory validation simulates extreme conditions to verify coil insulation, resistance stability, and heat dissipation.

Thermal Validation Tests:

-

Constant Temperature Load Test: 180°C for 500 hours, resistance drift ≤2%.

-

Thermal Shock Test: −40°C ↔ +180°C, 500 cycles, no enamel cracking.

-

Power-On Endurance: 300,000 switching cycles, voltage drop <3%.

Infrared thermography during testing confirms uniform heat distribution across coil windings, preventing localized burnout—a key cause of generic coil failures.

5. Electrical and Magnetic Efficiency Evaluation

KASEN engineers measure the interaction between current input and magnetic output through B-H curve testing (magnetic flux density vs. magnetic field strength).

This enables fine-tuning of coil geometry to achieve maximum efficiency at rated voltage without saturation.

Results Summary:

-

Magnetic flux density (Bmax): 1.75 T

-

Core loss reduction: −12% through optimized lamination thickness

-

Inductance tolerance: ±3% across 10,000 samples

These precision controls ensure every coil’s electromagnetic signature matches its design blueprint.

6. Quality Control and Data Traceability

Every coil used in KASEN’s automotive air conditioner clutch system is traceable from copper spool to finished assembly.

In-Line Quality Checks Include:

-

Resistance measurement at three temperature points (20°C, 100°C, 180°C)

-

High-voltage dielectric test (2,000V for 1 minute)

-

Automated polarity and continuity verification

-

Barcoded data upload to the MES database

This system ensures 100% traceability for OEM clients and supports batch recall analysis when required.

7. Environmental Reliability and Moisture Protection

In humid regions, coil degradation is often accelerated by condensation or corrosive gas exposure.

KASEN addresses this through multi-layer protection:

-

Epoxy potting for moisture sealing

-

Silicone gasket interface between coil housing and compressor body

-

Surface coating meeting ASTM B117 500-hour salt spray resistance standard

This guarantees stable magnetic response even in coastal or high-humidity conditions.

KASEN: Magnetism Engineered for Efficiency

Through precise coil engineering, exhaustive testing, and robust environmental protection, KASEN ensures each automotive air conditioner clutch performs consistently under every operational challenge.

These design principles translate into smoother engagement, longer service intervals, and higher customer satisfaction.

To explore KASEN’s full range of clutch systems, design specifications, and OEM cooperation options, please visit the KASEN homepage or reach our technical team via the contact page.

FAQ: Coil Performance and Design Validation

Q1. Why is Class H insulation necessary for A/C clutch coils?

Because coil temperature can exceed 160°C under continuous operation, Class H ensures long-term dielectric integrity.

Q2. What causes coil resistance drift over time?

Thermal aging and enamel degradation; KASEN mitigates this with dual-layer insulation and epoxy encapsulation.

Q3. How does coil design affect compressor efficiency?

Efficient coils reduce electrical losses, leading to quicker engagement and lower mechanical drag.

Q4. Are KASEN coils compatible with both 12V and 24V systems?

Yes—custom winding configurations are available for passenger, commercial, and electric vehicle platforms.