Performance Stability Under Extreme Conditions: Inside KASEN’s Automotive Air Conditioner Clutch System

Engineering a Stable Cooling Heart for Every Vehicle

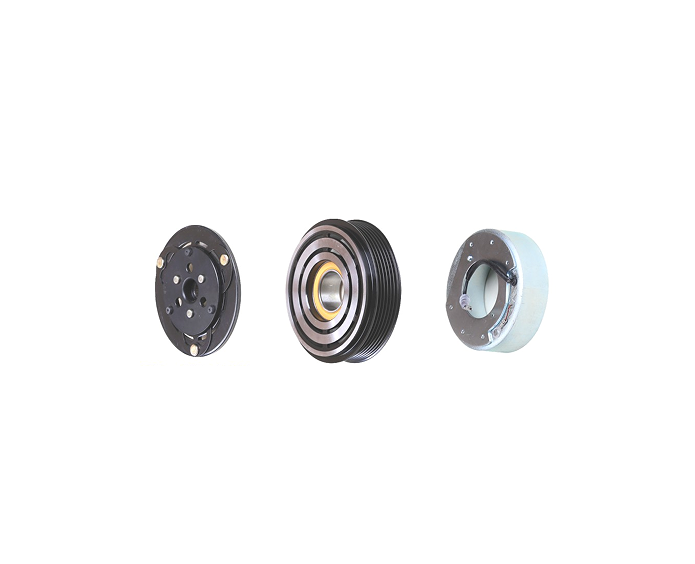

The automotive air conditioner clutch is the control gate of the entire A/C system—responsible for engaging and disengaging compressor torque precisely as cabin cooling demands change.

KASEN engineers each clutch as a critical mechanical-electrical interface, balancing torque transmission, electromagnetic response, and temperature control to ensure consistent performance across environments from freezing winters to tropical heat.

1. Reinforced Structural Design for Dynamic Load Stability

The clutch assembly endures constant cycles of acceleration, torque reversal, and vibration from the engine.

KASEN employs a reinforced structure design optimized through finite element analysis (FEA) to eliminate stress concentrations at the hub and pulley interface.

| Design Feature | Function | Benefit |

|---|---|---|

| Dual-bearing load path | Distributes torque evenly | Prevents bearing fatigue |

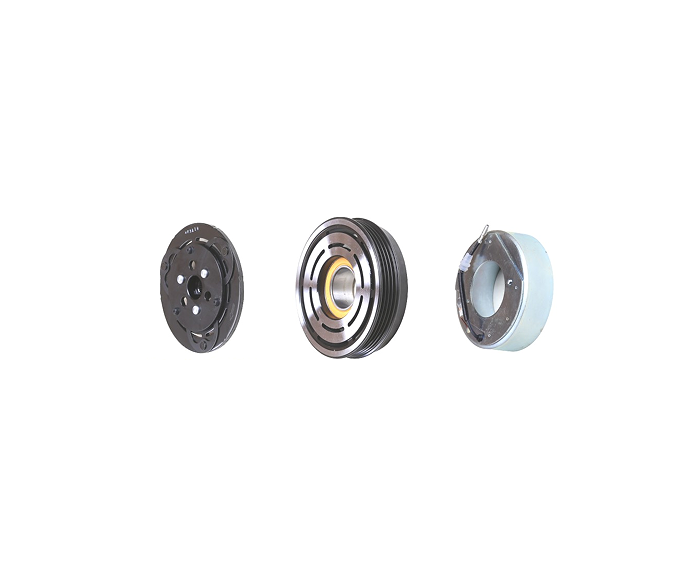

| Optimized air gap (0.35–0.45 mm) | Maintains precise magnetic pull | Reduces engagement noise |

| Laser-balanced pulley | Achieves G2.5 dynamic balance | Low vibration at 6,000+ RPM |

| High-precision rivet joints | Ensures long-term axial alignment | Improves torque consistency |

Each automotive air conditioner clutch undergoes dimensional inspection to guarantee tolerance within ±0.03 mm, critical for consistent engagement torque.

2. Thermal Management: Designed for Heat Dissipation and Longevity

Continuous operation of an air-conditioning system in hot climates subjects the clutch to repeated heating.

KASEN’s thermal management strategy ensures components remain within safe operating limits.

Engineering Solutions Include:

-

Ventilated pulley structure to increase heat dissipation efficiency by 28%.

-

High-conductivity alloy housing that evenly spreads thermal load from the coil.

-

Graphite-ceramic friction lining maintaining coefficient stability up to 220°C.

-

High-temperature epoxy insulation to preserve coil integrity during overloads.

Thermal testing shows that KASEN clutches operate 25–30°C cooler than average aftermarket equivalents during continuous cycling.

3. Noise and Vibration Control: Smooth Engagement Under All Conditions

NVH (Noise, Vibration, and Harshness) is a key differentiator in modern vehicle comfort.

KASEN conducts semi-anechoic chamber testing to fine-tune its clutch system’s acoustic signature.

Key NVH Enhancements:

-

Micro-textured friction surfaces prevent “stick-slip” engagement noise.

-

Pulley damping grooves absorb transient vibration waves.

-

Polymer-cushioned hub spacers lower structure-borne resonance by 35%.

-

Precision air gap adjustment reduces clunking under rapid cycling.

Real-world validation under idle and acceleration shows sound pressure levels below 58 dB(A)—a benchmark for quiet operation in premium vehicles.

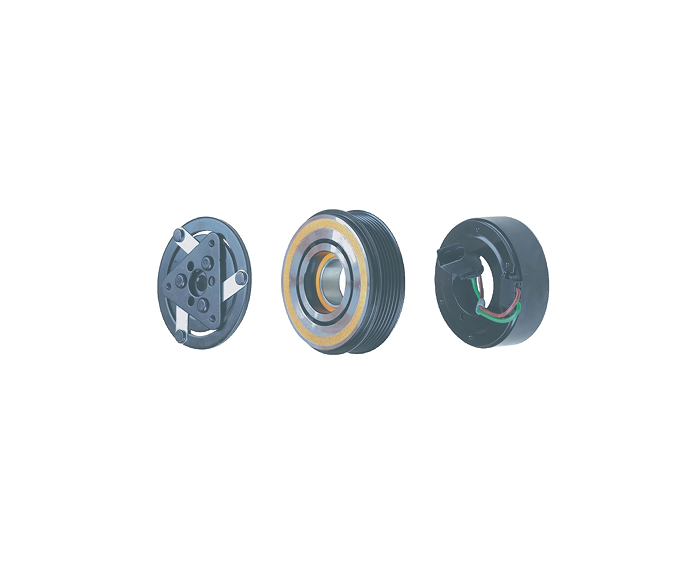

4. Electrical Coil Efficiency and Magnetic Precision

The electromagnetic coil is the actuation core of every automotive air conditioner clutch.

KASEN’s design prioritizes both magnetic strength and electrical stability to achieve reliable engagement even under voltage fluctuations.

| Parameter | KASEN Specification | Industry Standard |

|---|---|---|

| Coil Resistance | 3.8 Ω ± 0.05 | ± 0.2 |

| Voltage Range | 10.5–14.5 V | 11–14 V |

| Magnetic Pull Force | ≥ 450 N | 350–400 N |

| Response Time | ≤ 0.04 s | 0.08 s typical |

Through automatic winding and epoxy encapsulation, KASEN ensures magnetic field uniformity, preventing uneven engagement or partial slippage during operation.

5. Durability Validation: Long-Term Reliability Proven by Testing

Durability defines true value.

Each automotive air conditioner clutch undergoes accelerated life testing replicating five years of continuous use—covering torque cycling, temperature stress, and dynamic engagement tests.

Endurance Results:

-

300,000+ engagement cycles with torque retention ≥ 97%.

-

No insulation degradation after 500-hour high-temperature exposure.

-

Friction surface wear < 0.03 mm after full test sequence.

-

Stable engagement voltage even under coil temperature at 180°C.

These numbers are not theoretical—they represent KASEN’s consistent test outcomes validated by OEM-level quality audits.

6. Environmental and Corrosion Resistance

To ensure performance across global markets, KASEN subjects its clutches to multi-environmental stress tests:

| Test Type | Condition | Result |

|---|---|---|

| Salt Spray | 500 hours (ASTM B117) | No corrosion or coating peel |

| Humidity Resistance | 95% RH, 48 hours | Electrical insulation maintained |

| Thermal Cycling | −40°C to +180°C, 500 cycles | No warping or performance loss |

This ensures the automotive air conditioner clutch operates flawlessly across coastal, desert, and alpine climates without degradation.

7. Application Integration and Custom Adaptation

KASEN’s engineering team collaborates with global OEMs to adapt clutch assemblies for varied compressor platforms and vehicle architectures:

-

12V and 24V coil options for passenger and commercial vehicles.

-

Custom torque tuning for electric, hybrid, and fuel-based compressors.

-

Optional low-noise pulleys for EV thermal systems.

-

Complete validation documentation for regional homologation compliance.

This flexibility allows seamless integration into modern HVAC systems worldwide.

KASEN: Reliability Engineered for Real-World Demands

At KASEN, reliability is not tested—it’s designed into every automotive air conditioner clutch.

Through meticulous engineering, endurance validation, and real-world adaptation, each unit achieves OEM-grade consistency for every market and climate.

For cooperation opportunities, technical consultation, or OEM integration details, please visit the KASEN homepage or reach our engineering team via the contact page.

FAQ: Automotive Air Conditioner Clutch Performance

Q1. What makes KASEN clutches more reliable than standard aftermarket units?

High-tolerance machining, heat-resistant materials, and complete OEM validation ensure consistent long-term performance.

Q2. How does KASEN prevent noise during clutch engagement?

By balancing each pulley dynamically and using micro-textured friction surfaces to eliminate stick-slip noise.

Q3. Can KASEN provide 24V clutches for heavy vehicles?

Yes, both 12V and 24V configurations are available with customized magnetic tuning.

Q4. What environments are KASEN clutches tested in?

Thermal cycling, salt spray, humidity, and high-altitude pressure tests to replicate global climate conditions.