Assembly Precision and Quality Control Behind Every KASEN Automotive Air Conditioner Clutch

Building Consistency Into Every Production Stage

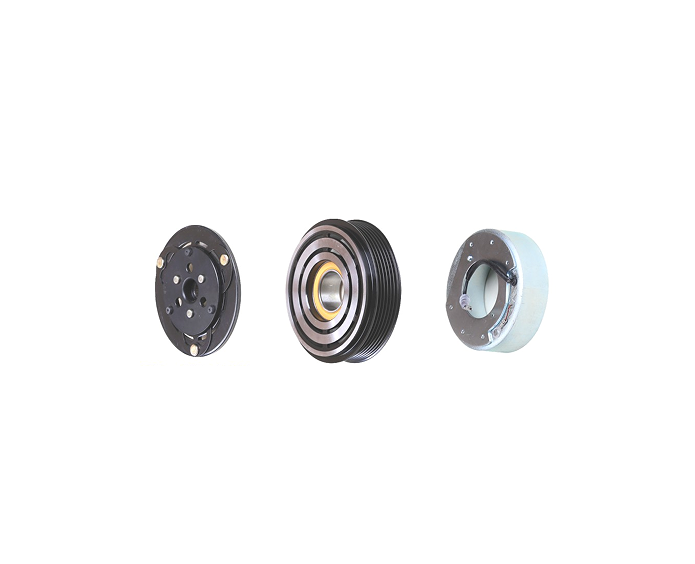

Each automotive air conditioner clutch from KASEN is not just assembled—it is engineered through a data-driven, precision-controlled process.

From raw material input to final torque validation, every stage follows IATF 16949 and ISO 9001 standards, ensuring that no clutch leaves the production line without verifiable traceability and test certification.

The company’s quality model combines automated assembly, in-line digital measurement, and post-assembly simulation testing to guarantee that every clutch behaves identically under real-world stress.

1. Component Preparation: Clean, Measured, and Verified

Consistency begins long before assembly.

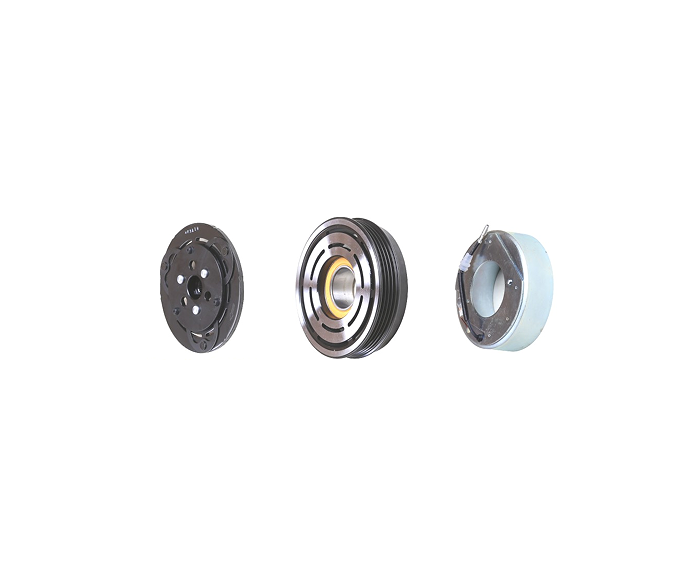

Each pulley, armature, and coil undergoes 100% dimensional verification using laser micrometry and optical comparators.

| Component | Measured Parameter | Tolerance (mm) | Inspection Method |

|---|---|---|---|

| Pulley | Concentricity, groove width | ±0.03 | Laser concentricity test |

| Hub | Bore alignment, surface finish | ±0.02 | CMM coordinate measurement |

| Armature Plate | Flatness, hardness | ±0.01 | Surface profilometer |

| Coil | Resistance and insulation | ±0.05 Ω | Digital ohmmeter & HV test |

Parts are stored in humidity-controlled zones, preventing contamination before robotic handling.

2. Automated Assembly Line Integration

KASEN’s clutch production line integrates six-axis robotic arms, servo-controlled press-fit stations, and automated screw torque systems.

This ensures uniform assembly torque, optimal pressure alignment, and repeatable air gap accuracy.

Core Assembly Operations Include:

-

Robotic bearing press-fit: ±0.01 mm accuracy using hydraulic servo control.

-

Coil installation with camera alignment: AI-based image recognition ensures perfect orientation.

-

Pulley-balancing calibration: Real-time vibration sensors dynamically correct imbalance to G2.5 grade.

-

Shim adjustment automation: Thickness compensation automatically applies per torque feedback data.

Each automotive air conditioner clutch assembled on the line is assigned a unique serial code embedded in its QR traceability label.

3. Torque and Magnetic Field Validation

After mechanical assembly, the next critical step is validation.

KASEN’s test benches simulate real compressor load to verify clutch engagement torque, pull force, and heat rise behavior.

| Test Parameter | Standard Value | Tolerance Range | Test Frequency |

|---|---|---|---|

| Engagement Torque | ≥ 90 N·m | ±2 N·m | Every 5 units |

| Coil Resistance | 3.8 Ω | ±0.05 Ω | 100% inspection |

| Pull Force | ≥ 450 N | ±10 N | 100% inspection |

| Air Gap | 0.40 mm | ±0.05 mm | 100% inspection |

| Thermal Rise (2 min) | ≤ 35°C | — | Random sampling |

Real-time data collection software uploads all parameters to the MES (Manufacturing Execution System), forming digital production records linked to each batch number.

4. Heat and Durability Simulation Testing

Before shipment, each batch of automotive air conditioner clutch units undergoes accelerated reliability testing.

These include heat cycling, vibration endurance, and magnetic fatigue under controlled laboratory conditions.

KASEN Endurance Simulation Parameters:

-

Heat cycle: −40°C → +180°C for 500 cycles

-

Vibration test: 5–2,000 Hz random vibration for 8 hours

-

Torque cycling: 300,000 continuous engagements

-

Voltage fluctuation: 10.5V–14.5V under dynamic load

Post-test analysis confirms torque retention ≥97% and zero electrical insulation loss, proving long-term reliability for real-world use.

5. Quality Inspection and Statistical Process Control

To maintain consistency across thousands of units, KASEN applies SPC (Statistical Process Control) and Six Sigma methodologies.

Each production batch is monitored for deviation trends, and corrective measures are automatically triggered when control limits are approached.

In-Line Sensors Monitor:

-

Torque fluctuation and pull current

-

Coil temperature and magnetic efficiency

-

Bearing rotation resistance

-

NVH parameters via acoustic microphones

Anomalous readings result in automatic rejection and root cause traceability within minutes.

6. Packaging, Labeling, and Global Traceability

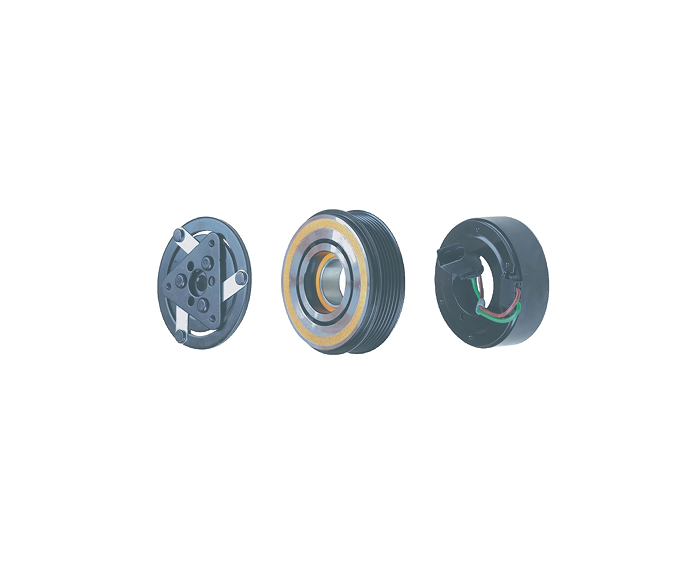

After passing validation, each clutch is assigned a QR-coded digital passport that records its entire production history—

from component lot numbers to test curves and inspection personnel IDs.

Packaging follows anti-static, anti-vibration standards for both OEM and aftermarket delivery.

For bulk shipments, palletized cartons undergo drop, tilt, and vibration tests to ensure mechanical safety during long-distance logistics.

7. From Factory Floor to Vehicle System Integration

The manufacturing excellence of KASEN translates directly to on-road performance.

Automakers and Tier-1 suppliers trust KASEN’s production system for its consistency across global markets.

Every automotive air conditioner clutch assembled under this process delivers predictable electromagnetic behavior, torque stability, and minimal noise—even after years of service.

KASEN: Quality Built Into Every Stage

At KASEN, assembly is not the final step—it is the physical proof of engineering precision.

Through automation, real-time validation, and full traceability, KASEN ensures every product meets OEM-level standards of endurance and reliability.

For technical collaboration, OEM supply, or custom clutch solutions, please visit the KASEN homepage or contact our production engineering team via the contact page.

FAQ: Automotive Air Conditioner Clutch Quality and Assembly

Q1. How does KASEN ensure torque consistency in each unit?

Every clutch undergoes dynamic torque calibration and magnetic pull testing with automated sensors before shipment.

Q2. What is the average production tolerance maintained by KASEN?

Most critical parameters are controlled within ±0.03 mm, exceeding standard aftermarket precision levels.

Q3. Can KASEN provide traceable reports for OEM customers?

Yes, each clutch carries a QR code linked to its digital test report and batch traceability record.

Q4. How often are test equipment and gauges recalibrated?

All measuring devices are recalibrated every 90 days under ISO/IEC 17025 standards.