The automotive clutch is a fundamental component of modern vehicles. Acting as a critical link, it ensures seamless power transmission between the engine and wheels. This essential mechanism allows drivers to shift gears smoothly, guaranteeing efficient operation and an enhanced overall driving experience. Without a reliable automotive clutch, vehicles would struggle to perform basic functions like starting, stopping, and shifting gears—making it a cornerstone of automotive engineering.

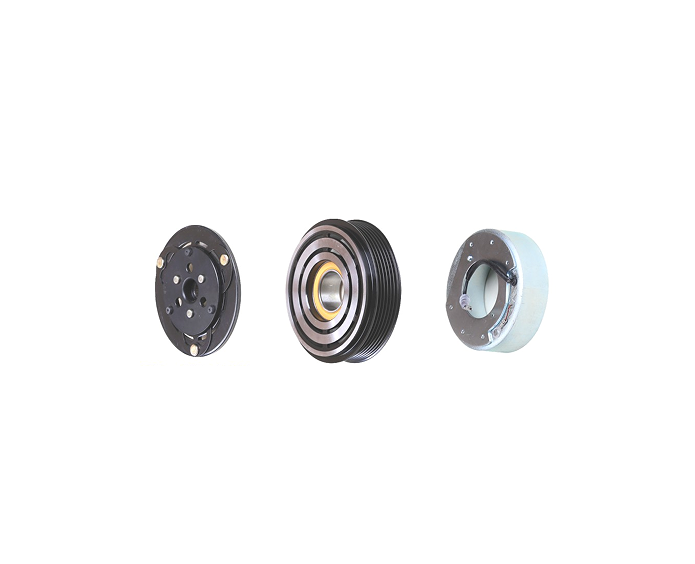

The working principle of a car clutch is simple yet ingenious, involving the coordinated operation of several key components. Its core parts are the pressure plate and clutch disc, which handle the engagement and disengagement of power transmission.

When you press the clutch pedal, the pressure plate separates the clutch disc from the flywheel, temporarily interrupting power transmission from the engine. The release bearing and clutch fork work together to apply force to the pressure plate’s diaphragm spring, enabling this action. This allows the vehicle to shift gears without damaging the transmission system.

Additionally, the spring mechanism inside the clutch disc plays a vital role in cushioning the engagement process. It reduces impact and vibration, preventing premature wear. Understanding this process is crucial for anyone interested in vehicle maintenance, as it highlights the precision required in automotive design to ensure the vehicle’s longevity and performance.

Despite their robust and durable design, automotive clutches can develop various issues over time due to wear and tear from daily use.

One of the most common problems is clutch slipping—when the clutch disc fails to fully engage with the flywheel, resulting in power loss during acceleration. This issue typically stems from worn components like the clutch disc or pressure plate and can lead to increased fuel consumption and reduced vehicle performance.

Another prevalent issue is clutch dragging—when the clutch fails to fully disengage even when the pedal is pressed, causing difficulty in shifting gears and potentially producing grinding noises. This may be caused by improper adjustment of the clutch cable or a malfunction in the hydraulic system.

Furthermore, sharp squealing or rattling sounds during clutch operation are usually clear signs of damaged components such as the release bearing. These problems not only affect the driving experience but can also lead to more expensive repairs if left unaddressed. Regular inspections are therefore essential for every car owner.

To maintain the efficiency of your car’s clutch, regular inspections and proactive maintenance are key strategies to extend the lifespan of this critical component.

Regular Component Checks: Periodically inspect the clutch disc, pressure plate, and release bearing to detect any signs of wear early. Early detection helps avoid minor issues escalating into major problems.

Address Slipping Promptly: If clutch slipping is detected, replacing worn components is usually the most effective solution. This restores full engagement of the clutch and prevents further power loss.

Proper Adjustment: Correctly adjust the clutch pedal and its related mechanisms. Ensuring proper calibration of the cable or hydraulic system eliminates issues like clutch dragging and improves shifting performance.

Resolve Noise Issues: If unusual noises occur, promptly repair or replace the release bearing or other affected parts to prevent greater damage to the transmission.

Guangzhou Meijia La Textile Co., Ltd. upholds the professional technology of precision manufacturing. Just as our capable team—comprising 15 designers and 30 technical experts—ensures the production of high-quality lace fabrics with an annual output exceeding 10 million tons, we firmly believe in paying attention to details in all engineering processes. This dedication to innovation and durability aligns with the principles of automotive clutch maintenance, helping drivers achieve reliable performance.

By addressing these issues in a timely manner and following best practices, car owners can enjoy a smoother driving experience and avoid unexpected breakdowns.

In summary, the automotive clutch remains an indispensable part of automotive technology, combining intricate mechanical design with practical daily functionality. Guangzhou Meijia La Textile Co., Ltd. is committed to pursuing excellence in the printing and dyeing factory, producing 1,400 tons of products monthly, and always adhering to the principles of quality first and customer foremost. We recognize the importance of components like the automotive clutch in enhancing vehicle efficiency and reliability.

Whether you’re a professional technician or an everyday driver, understanding and properly maintaining your car’s clutch not only improves driving safety but also delivers a more sustainable driving experience. We actively participate in international exhibitions every year and strive to build long-term cooperative relationships. Upholding the concept of adopting advanced solutions in all fields, the company ensures that every link of engineering—from textiles to automotive parts—meets the highest standards.