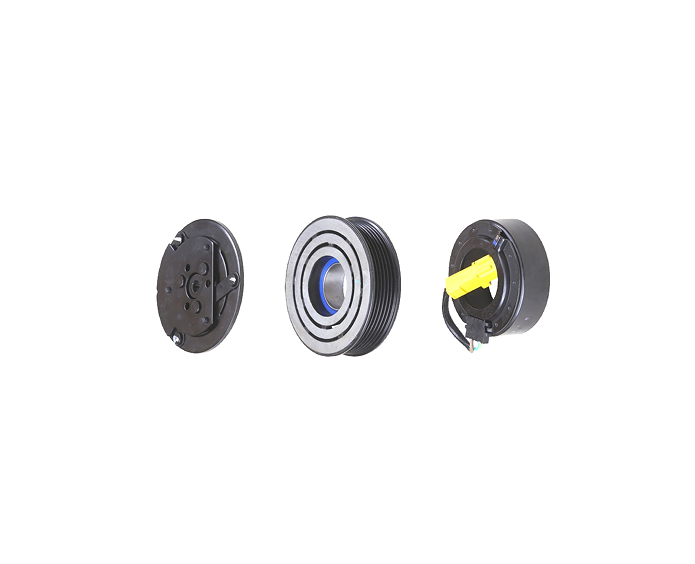

A/C Compressor Clutch and Fuel Efficiency: Intelligent Power Transfer for Energy-Saving Vehicle Systems

The Hidden Link Between Cooling and Fuel Economy

In modern automotive design, every mechanical system affects fuel efficiency—including the A/C compressor clutch.

While it seems like a minor component, its engagement timing, friction characteristics, and torque transmission efficiency directly impact how much engine power is diverted to air-conditioning.

When engineered with precision, the clutch ensures that the compressor runs only when needed, minimizing parasitic drag and conserving energy. KASEN’s clutch technology bridges thermal comfort and energy discipline, aligning with the industry’s global push toward sustainability.

Energy Flow and Load Reduction: How the Clutch Contributes

In conventional A/C systems, the compressor draws power continuously from the engine via the belt. The clutch, however, serves as a dynamic power gate—engaging only when cabin temperature or humidity demand cooling.

By disconnecting the compressor during idle or low-load conditions, the clutch prevents unnecessary energy drain.

| Operating Mode | Clutch Status | Power Consumption | Effect on Fuel Economy |

|---|---|---|---|

| Cooling ON (High Demand) | Engaged | 3–5 HP engine load | Normal operation |

| Cooling OFF / Idle | Disengaged | 0 HP | Saves up to 0.2 L/100 km |

| ECO Mode / Hybrid | Controlled engagement | 1–2 HP | Improves engine efficiency by ~5% |

KASEN’s precision electromagnetic control ensures instant response without torque lag, maximizing energy savings without sacrificing cabin comfort.

Magnetic Efficiency and Electrical Optimization

At the heart of Kasen’s design lies magnetic field optimization.

A typical clutch coil converts electrical energy into a magnetic field that engages the friction plate—but inefficient designs leak magnetic flux, wasting current and generating unnecessary heat.

KASEN’s energy-optimized design features:

-

Low-resistance copper windings (≤0.08 Ω/m) reducing power draw.

-

Closed-loop magnetic circuit concentrating flux around the engagement surface.

-

Smart current regulation through high-efficiency insulation resin minimizing energy loss.

-

Quick-release magnetic field decay, cutting disengagement delay to under 0.04 seconds.

These engineering refinements allow up to 10–12% lower current consumption, contributing directly to improved alternator efficiency and reduced engine load.

Friction and Torque Control for Mechanical Efficiency

Mechanical drag is another hidden source of inefficiency.

Every engagement generates friction and torque loss—especially when air gaps or bearing tolerances are inconsistent.

KASEN employs CNC-calibrated air gaps (0.4–0.6 mm) and graphite-based friction plates that provide smooth contact while minimizing energy-wasting slippage.

Key Performance Highlights:

-

Torque transmission efficiency ≥ 95%

-

Engagement noise < 58 dB

-

Dynamic runout ≤ 0.02 mm

-

Belt slip resistance +30% improvement over generic designs

By minimizing both magnetic and mechanical loss, the Kasen clutch effectively reduces the net compressor drive load, improving vehicle fuel efficiency by up to 4–6% in combined cycles.

Integrating with Smart Vehicle Control Systems

Modern vehicles—especially hybrids and EV-based platforms—use intelligent control modules to manage A/C compressor engagement.

KASEN clutches are designed for direct integration with these systems, supporting variable-speed control and real-time energy optimization.

Key integration features include:

-

CAN-compatible control signals for ECU monitoring.

-

Thermal feedback sensors embedded in coil assemblies.

-

Predictive control algorithms to balance cooling load and fuel economy.

-

Voltage stability tolerance ±0.5 V for reliable operation in regenerative braking environments.

This level of system compatibility allows Kasen clutches to operate seamlessly in energy-conscious platforms without additional wiring or control adaptation.

Real-World Impact: Energy Savings Over Vehicle Lifespan

While the power savings from a single clutch cycle may appear small, over time they accumulate significantly.

Based on Kasen’s field data from OEM fleet applications:

| Vehicle Type | Average Annual Mileage | Fuel Saved via Efficient Clutch | CO₂ Reduction |

|---|---|---|---|

| Passenger Car | 20,000 km | 30–45 L/year | 75–100 kg CO₂ |

| Light Commercial | 40,000 km | 70–100 L/year | 160–200 kg CO₂ |

| Hybrid SUV | 25,000 km | 50 L/year | 120 kg CO₂ |

This demonstrates that even a small mechanical upgrade—when multiplied across millions of vehicles—can yield large environmental and economic benefits.

Sustainable Manufacturing and Lifecycle Efficiency

Energy efficiency begins long before the clutch reaches the vehicle.

KASEN’s production lines are designed around low-emission manufacturing principles:

-

CNC machining centers with energy-regenerative servo systems.

-

Heat recycling furnaces that reuse waste heat during pulley hardening.

-

Zero-lead epoxy coatings compliant with RoHS and REACH.

-

ISO 14001 environmental certification ensuring full lifecycle accountability.

The result is not only an efficient component—but an eco-responsible manufacturing process aligned with global sustainability goals.

Partner with KASEN for Energy-Optimized Cooling Systems

With growing regulatory pressure on fuel economy and emissions, component-level efficiency has never been more crucial.

KASEN’s A/C compressor clutches deliver quantifiable energy savings through smarter magnetic design, low-friction materials, and perfect mechanical alignment.

To explore technical specifications, OEM integration opportunities, or energy-efficiency studies, visit the KASEN homepage or reach out to our team via the contact page.

FAQ: A/C Compressor Clutch and Fuel Efficiency

Q1. How does the clutch improve fuel economy?

By disconnecting the compressor during idle or low cooling demand, reducing engine drag and saving fuel.

Q2. What’s the main efficiency advantage of Kasen’s design?

Lower magnetic loss, faster engagement, and smoother torque transfer—together reducing power draw.

Q3. Is this clutch suitable for hybrid and stop-start systems?

Yes, Kasen clutches are designed for rapid cycling and ECU-controlled environments.

Q4. Can these savings be measured in real driving conditions?

Yes. Field data from OEM partners show consistent 4–6% improvement in combined fuel consumption.