A/C Compressor Clutch: Precision Control for Reliable Cooling and Energy Efficiency

The Key to Intelligent Compressor Engagement

In automotive air-conditioning systems, the A/C compressor clutch acts as the bridge between the engine and the cooling circuit. Its precision determines whether the compressor operates efficiently, quietly, and reliably.

When the coil is energized, magnetic force draws the clutch plate toward the pulley, locking them together and transmitting torque to the compressor shaft. When cooling demand drops, the clutch disengages, conserving power and reducing fuel consumption.

A perfectly engineered clutch must balance magnetic power, mechanical strength, and dynamic stability—three domains that define Kasen’s engineering philosophy.

Component Integration and Functional Synergy

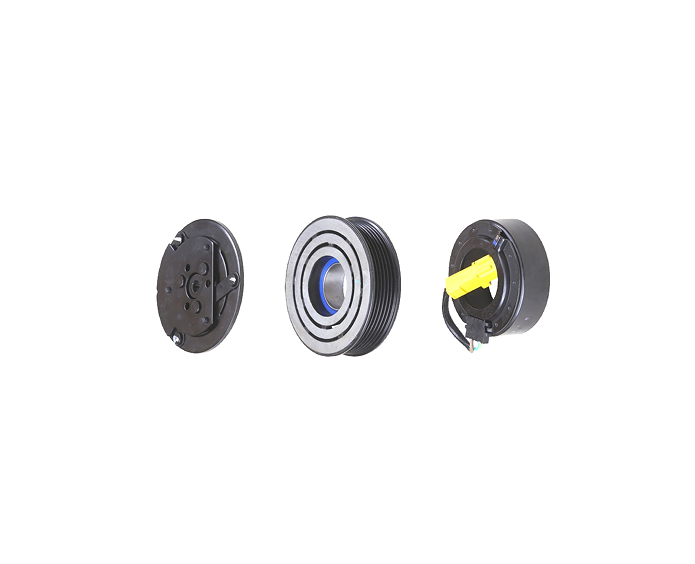

A complete A/C compressor clutch consists of three critical components:

| Component | Function | KASEN Engineering Focus |

|---|---|---|

| Electromagnetic Coil | Generates magnetic field to engage clutch | High-purity copper winding, Class H insulation |

| Pulley & Bearing | Transfers rotational energy from the belt | Dynamic balance ≤0.02 mm, low-noise bearing system |

| Clutch Plate (Hub) | Connects compressor shaft to pulley face | Heat-treated alloy, friction-optimized surface |

These components are produced and calibrated as a single integrated system to maintain consistent torque transfer, prevent vibration, and eliminate uneven wear.

Magnetic Efficiency and Electrical Optimization

Magnetic performance defines how quickly and accurately the clutch engages. KASEN’s electromagnetic design employs oxygen-free copper wire with ±1.5% resistance tolerance, ensuring stable current flow and consistent magnetic flux density.

Typical Magnetic Parameters:

-

Coil Resistance: 3.8–4.2 Ω (12V system)

-

Magnetic Pull: 350–480 N

-

Response Time: <0.05 s

-

Power Draw: <60 W under load

To ensure long-term stability, every coil is encapsulated with thermally conductive epoxy, protecting it from moisture, dust, and vibration—common causes of field failure in low-grade aftermarket parts.

Dynamic Balancing and NVH Reduction

The pulley and bearing subsystem defines both the smoothness and acoustic performance of the compressor. Any imbalance at high rotational speeds causes belt flutter, noise, and mechanical wear.

KASEN eliminates these risks through:

-

Dynamic balancing calibration (up to 6,000 RPM testing)

-

High-precision CNC machining for flatness and runout control

-

Noise optimization (<58 dB) verified in real-world vehicle tests

-

Grease-sealed bearings rated for 180 °C continuous operation

This precision ensures quiet operation and extended service life, even under continuous stop-and-go urban driving cycles.

Thermal Endurance and Surface Durability

Heat is the enemy of every clutch system. KASEN’s A/C compressor clutches use advanced surface treatments and composite materials to maintain structural integrity and friction consistency.

Key durability technologies include:

-

Nitrided clutch plate surfaces for hardness and oxidation resistance

-

Ventilated pulley grooves enhancing airflow and cooling

-

Graphite-infused friction coatings reducing glazing and slippage

-

Thermal cycle validation under −30 °C to +180 °C

Each clutch assembly undergoes 300,000+ engagement cycle testing, ensuring reliability over a full vehicle lifespan.

OEM Compatibility and Maintenance Efficiency

KASEN’s clutches are engineered for universal compatibility with major compressor systems, including Denso, Sanden, Delphi, and Valeo.

OEM and distributor advantages:

-

Plug-and-play fitment across multiple vehicle models

-

Consistent engagement torque under variable voltages

-

Reduced installation time through pre-calibrated air gaps (0.4–0.6 mm)

-

Simplified maintenance via modular replacement kits

By integrating standardization and precision, KASEN’s clutches support both OEM production lines and professional aftermarket service centers worldwide.

Comprehensive Testing and Quality Control

All KASEN compressor clutches are produced under ISO/TS 16949-certified processes and verified through:

-

Resistance and inductance testing for every coil

-

Torque endurance testing under simulated road vibration

-

Dynamic balancing verification at operating RPM

-

Salt-spray corrosion testing (500+ hours) for exposed metal surfaces

-

Dimensional inspection using laser metrology for each assembly batch

This data-driven process guarantees traceable quality and consistent performance across all Kasen manufacturing lots.

Partner with KASEN for Advanced Clutch Technology

With over two decades of experience in automotive A/C systems, KASEN continues to lead in precision component engineering for compressors and clutch assemblies.

Its integrated manufacturing system—covering coil winding, friction coating, and dynamic balancing—ensures every product meets global OEM standards.

For detailed clutch specifications, voltage customization, or distributor cooperation, visit the KASEN homepage or contact our technical support via the contact page.

FAQ: A/C Compressor Clutch

Q1. What are the signs of a failing A/C compressor clutch?

Unusual noise, weak cooling, or belt squeal during engagement indicate coil or bearing wear.

Q2. Can a clutch be replaced without replacing the compressor?

Yes. KASEN provides direct-fit clutch kits designed for field replacement without full compressor removal.

Q3. How does coil resistance affect performance?

Incorrect resistance leads to unstable magnetic pull or overheating. KASEN calibrates each coil to ±1.5% tolerance for reliable engagement.

Q4. What maintenance is required?

Regularly check belt tension, clean connectors, and avoid running the A/C with low refrigerant levels to reduce clutch load.