Why Automotive Pressure Switches Are Non-Negotiable

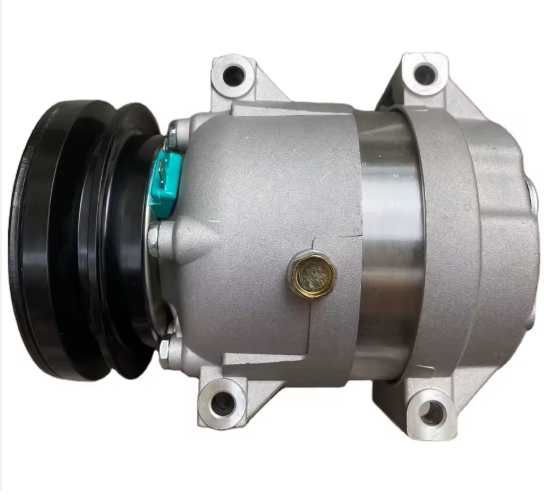

Modern vehicles rely on a delicate balance of fluid and gas pressures to operate smoothly—from engine oil and fuel systems to brakes and cooling circuits. At the center of this balance is the automotive pressure switch: a compact yet critical component that acts as a "pressure watchdog," continuously tracking levels and triggering alerts or adjustments when deviations occur.

Without a reliable pressure switch, the consequences can be severe. Imagine cruising on the highway when your check engine light suddenly flashes—only to discover the issue stems from a failing pressure switch that failed to detect low oil pressure. This not only disrupts your journey but also risks engine overheating, reduced brake efficiency, or even catastrophic system failure. Industry data underscores this risk: nearly 20% of vehicle breakdowns are linked to pressure management system malfunctions.

For drivers and fleet managers alike, investing in high-quality pressure switches isn’t just a maintenance choice—it’s a safety imperative. And at Guangzhou Meijia Textile Co., Ltd., we’ve leveraged our decades of precision engineering experience to craft pressure switches that rise to the demands of today’s automotive environments.

Core Working Principles of Automotive Pressure Switches

Automotive pressure switches operate on a deceptively simple yet highly precise mechanism, tailored to adapt to the dynamic needs of vehicle systems. Their functionality hinges on three key engineering pillars:

Pressure Sensing & Electrical Triggering

At the heart of every pressure switch lies a sensing element—typically a diaphragm, piston, or piezoelectric sensor—that responds to pressure changes. When the pressure in a target system (e.g., fuel line, brake hydraulic circuit) reaches a pre-calibrated threshold (either high or low), the sensing element deforms. This deformation closes or opens an internal electrical contact, sending an immediate signal to the vehicle’s ECU (Engine Control Unit) or directly activating a warning light (e.g., low oil pressure indicator) or system adjustment (e.g., regulating fuel injector flow).

For example, a brake pressure switch monitors hydraulic pressure in the brake lines. If pressure drops unexpectedly (a sign of a leak), the switch instantly alerts the ECU, which may engage safety protocols or illuminate the brake warning light—giving the driver critical time to react.

Real-Time Adaptability for Dynamic Conditions

Unlike static components, modern pressure switches deliver continuous, real-time monitoring that adapts to changing driving scenarios. A pressure switch in the engine oil system, for instance, doesn’t just check pressure once at startup—it adjusts its sensitivity to account for engine temperature (oil thins as it warms, reducing pressure) and load (pressure increases under acceleration). This adaptability ensures accurate readings across all conditions, from cold starts to high-speed towing.

Rugged Design for Harsh Environments

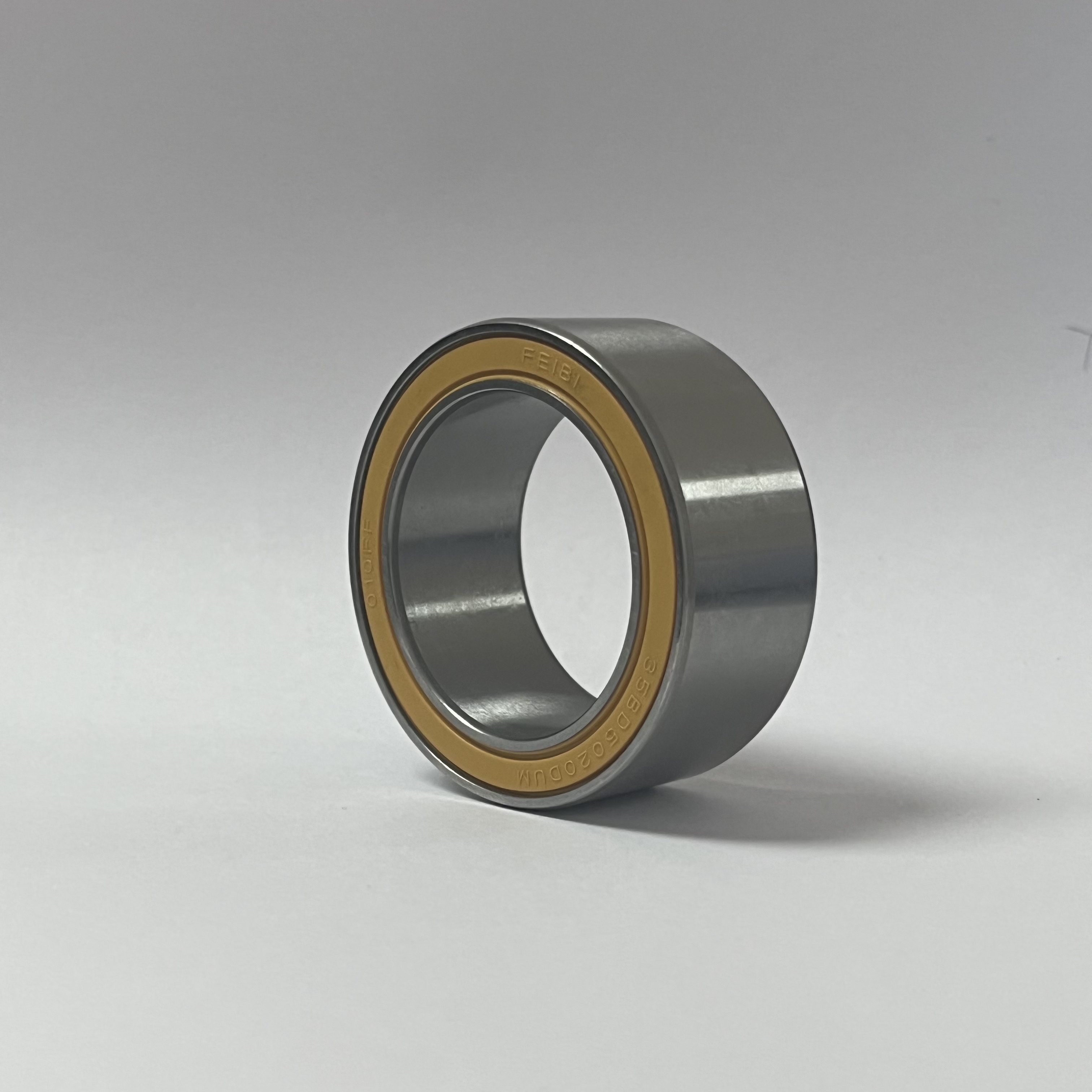

Vehicle engine bays and undercarriages are unforgiving: extreme temperatures (-40°C to 120°C), constant vibration, road salt, and fluid exposure all threaten component longevity. Our pressure switches counter these challenges with robust construction: corrosion-resistant steel or reinforced plastic housings seal internal components from contaminants, while shock-absorbent mounts reduce vibration damage. Many of our models feature a protective golden coating—more than just aesthetic, this layer acts as a barrier against rust and wear, extending service life by up to 50% compared to standard switches.

Common Pressure System Problems & Our Targeted Solutions

Even the most well-maintained vehicles face pressure system issues—often rooted in sensor failure, environmental damage, or poor design. Here’s how our advanced pressure switches address the industry’s most persistent pain points:

Inaccurate Readings & False Alerts

The Problem: Traditional pressure switches often suffer from "drift"—gradual loss of calibration due to temperature cycles or wear—leading to false warnings or missed critical alerts. Old-model switches may also fail to distinguish between normal pressure fluctuations and genuine faults, causing unnecessary panic or costly service calls.

Our Solution: We use high-precision piezoelectric sensing elements that maintain calibration within ±1% accuracy, even after 100,000+ operating hours. Each switch undergoes rigorous temperature and vibration testing during production to eliminate drift. Additionally, our proprietary signal-filtering technology distinguishes between transient fluctuations (e.g., temporary fuel pressure spikes during acceleration) and sustained faults, ensuring drivers only receive alerts when genuine issues arise.

Environmental Damage & Premature Failure

The Problem: Extreme heat, road salt, and moisture are the biggest enemies of pressure switches. Old-style switches with plastic housings or inadequate seals often corrode or short-circuit within 2-3 years, requiring frequent replacements and downtime.

Our Solution: Every switch we manufacture features a double-sealed housing with IP67/IP6K9K ingress protection—meaning it’s dust-tight and resistant to high-pressure water jets. We use marine-grade stainless steel for critical components and a ceramic coating on sensing elements to prevent corrosion. The result? A service life of 5+ years in even the harshest environments, from snowy winters to coastal salt air.

Poor Integration & Complex Installation

The Problem: Aftermarket pressure switches often require custom adapters or wiring modifications to fit different vehicle makes and models, increasing installation time and the risk of errors.

Our Solution: Our pressure switches feature a universal design with standardized connectors (compatible with 95% of passenger cars, trucks, and SUVs) and clear, color-coded wiring harnesses.醒目的标识 (Bold labeling) guides technicians through installation in under 30 minutes—no special tools required. For high-performance or specialty vehicles, we offer custom mounting brackets and calibration options to ensure seamless integration.

The Benefits of Our Precision Pressure Switches

Choosing our automotive pressure switches delivers more than just reliable performance—it unlocks tangible value for drivers, mechanics, and fleet operators:

-

Enhanced Safety: Real-time, accurate monitoring prevents catastrophic failures like engine seizure or brake fade, protecting drivers and passengers.

-

Improved Efficiency: By maintaining optimal pressure in fuel and oil systems, our switches reduce energy waste—boosting fuel economy by 3-5% in combustion vehicles and extending battery range in EVs.

-

Lower Maintenance Costs: Durable construction and long service life cut replacement frequency by 60% compared to standard switches. Predictive alerts also allow for proactive maintenance, avoiding costly emergency repairs.

-

Easy Compliance: Our switches meet global automotive standards (ISO/TS 16949, SAE J1939) and help vehicles adhere to emissions regulations by ensuring proper fuel and exhaust pressure management.

A Real-World Example

A regional delivery fleet recently switched to our pressure switches after struggling with frequent oil pressure-related breakdowns. Within six months, they reported a 40% drop in engine repair costs and a 3.2% increase in fuel efficiency—translating to $12,000 in annual savings across their 50-vehicle fleet. "The reliability has been game-changing," said their fleet manager. "We no longer have drivers stranded on the road due to faulty pressure alerts."

Our Commitment to Quality & Innovation

At Guangzhou Meijia Textile Co., Ltd., our expertise in precision manufacturing isn’t limited to textiles—we’ve applied the same rigorous attention to detail to automotive components for over a decade. Our skilled technicians and advanced production facilities (equipped with automated calibration and testing equipment) ensure every pressure switch meets our strict quality standards. We also actively participate in international automotive exhibitions to integrate the latest sensing technologies into our products—from smart sensors with IoT connectivity to eco-friendly materials that reduce environmental impact.

We believe a great product is only part of the solution. That’s why we offer technical support for installation, custom calibration services, and a 2-year warranty on all pressure switches—giving our customers peace of mind long after purchase.

Invest in Reliability, Invest in Safety

Automotive pressure switches may be small, but their impact on vehicle safety and performance is enormous. In an era where vehicle systems grow increasingly complex, settling for low-quality switches is a risk no driver or fleet can afford.

Our advanced pressure switches solve the root causes of pressure system failures—from inaccurate readings to environmental damage—delivering the reliability, efficiency, and safety modern drivers demand. Whether you’re a professional mechanic servicing client vehicles, a fleet manager looking to cut downtime, or a car enthusiast prioritizing performance, our solutions are engineered to exceed expectations.

Ready to experience the difference precision makes? Contact us today to learn how our automotive pressure switches can elevate your vehicle’s performance—and keep every journey safe and smooth.

Want to dive deeper? Ask us for our

Technical Specification Sheet—it includes detailed performance metrics, compatibility guides, and installation diagrams for our full pressure switch lineup.