Global Market Application and Regional Adaptation: How KASEN A/C Compressor Clutch Performs Across Diverse Climates

Engineering for Global Conditions

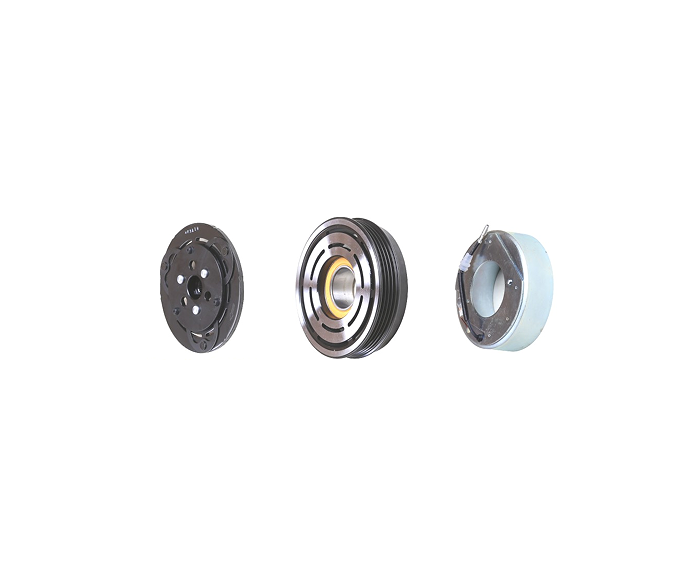

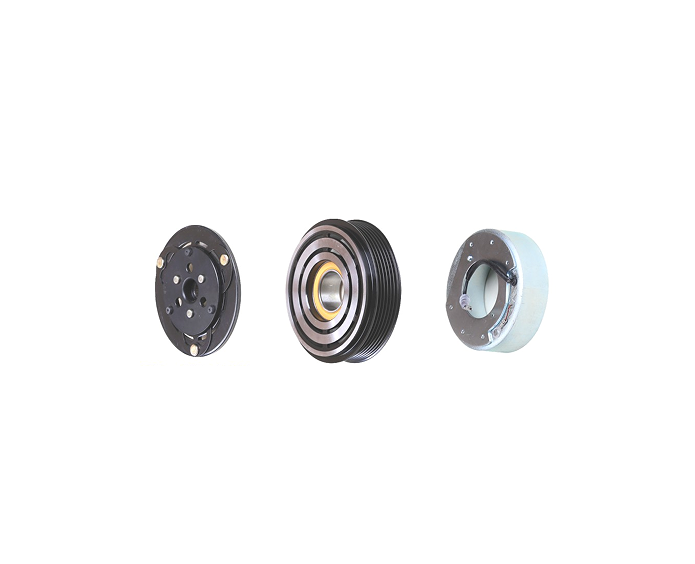

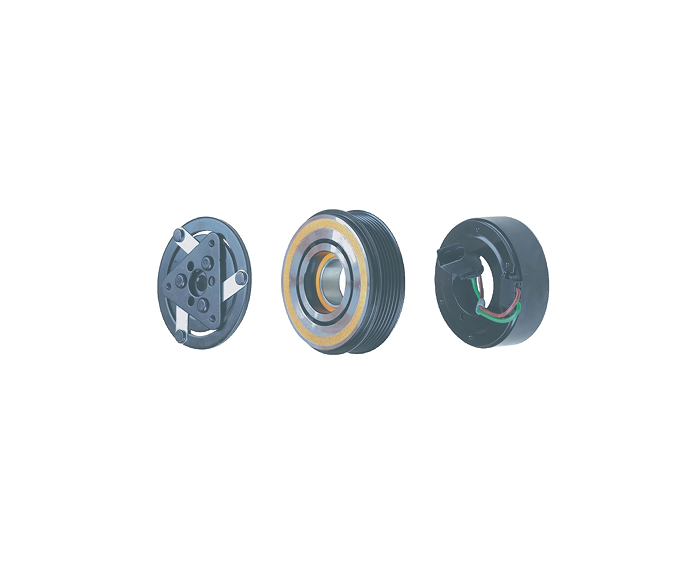

The A/C compressor clutch is a component that must endure vastly different conditions depending on where a vehicle operates.

In tropical regions, high humidity and heat test coil insulation and corrosion resistance; in cold climates, freezing cycles and oil viscosity challenge mechanical tolerances.

KASEN designs its A/C compressor clutch to maintain performance consistency across every market—whether a humid coastal city or an arid desert highway.

1. Tropical Climate Performance: Humidity and Heat Resistance

In Southeast Asia, South America, and coastal regions, air-conditioning systems face extreme humidity, salt exposure, and high thermal loads.

To ensure reliability, KASEN applies several tropical adaptation techniques:

-

Epoxy-encapsulated coils prevent moisture ingress and electrical leakage.

-

Triple-layer anti-corrosion coatings (phosphate + e-coat + epoxy topcoat) provide 500-hour salt spray protection.

-

High-temperature friction materials resist glazing and maintain torque stability at up to 200°C.

-

Precision-balanced pulleys ensure smooth engagement despite fluctuating belt tension.

These features allow the A/C compressor clutch to retain full magnetic and torque performance even in long-term high-humidity exposure.

2. Cold Climate Adaptation: Freeze-Resistant Performance

Vehicles in Northern Europe, Canada, and Russia operate in sub-zero conditions where lubricants thicken and metals contract.

KASEN engineers each A/C compressor clutch with cold-weather resilience in mind:

| Parameter | Cold Climate Challenge | KASEN Solution |

|---|---|---|

| Coil Activation Delay | Low temperature reduces magnetic efficiency | Low-resistance copper coil for consistent pull-in at −30°C |

| Bearing Lubrication | Grease thickening causes drag | Synthetic low-viscosity grease maintains fluidity |

| Friction Response | Surface hardening from cold | Micro-textured ceramic lining ensures contact stability |

| Condensation Corrosion | Freeze–thaw cycles cause rust | Epoxy coating with hydrophobic surface barrier |

The result: stable engagement timing and silent clutch operation, even in deep winter environments where other systems struggle.

3. Desert and Arid Zone Optimization

For Middle Eastern and Australian markets, A/C compressor clutch durability depends on heat dissipation and dust protection.

KASEN integrates heat-tolerant and contamination-resistant materials for desert-ready reliability:

-

Ventilated pulley design increases airflow by 25%, reducing coil temperature rise.

-

Dust-proof seals prevent sand ingress into the bearing chamber.

-

High-thermal-conductivity aluminum alloys enhance cooling under continuous load.

-

Graphite-based friction composites prevent heat glazing during prolonged idling.

In field testing at 45°C ambient temperatures, KASEN clutches maintained full torque with no thermal degradation—ensuring consistent cooling for heavy-duty or fleet vehicles.

4. High-Altitude and Variable Pressure Environments

At elevations above 2,000 meters, thinner air affects magnetic field efficiency and clutch torque transfer.

KASEN’s testing in plateau regions such as Tibet and the Andes led to optimization of coil geometry and current compensation algorithms, resulting in:

-

Stable engagement voltage across 10.5V–14V range.

-

Torque retention > 95% under reduced atmospheric density.

-

Faster clutch response due to adaptive winding design.

Such improvements ensure the A/C compressor clutch performs seamlessly in variable-pressure regions without requiring recalibration.

5. Regional Customization and OEM Compatibility

Each region demands unique system integration.

KASEN collaborates with local OEMs and distributors to tailor A/C compressor clutch configurations based on voltage systems, compressor models, and climate data.

Regional Adaptation Programs Include:

-

12V/24V coil versions for passenger and commercial vehicles.

-

Custom air gap calibrations for different compressor designs.

-

Coating and material adjustments for regional corrosion profiles.

-

Batch testing under region-specific temperature and humidity cycles.

This ensures global consistency in clutch performance while providing local flexibility for integration into diverse vehicle platforms.

6. Field Validation Across Continents

KASEN validates every A/C compressor clutch in real-world fleets before product release.

| Region | Test Duration | Ambient Conditions | Outcome |

|---|---|---|---|

| Southeast Asia | 12 months | 35–45°C / 90% RH | Stable magnetic efficiency, no corrosion |

| Northern Europe | 8 months | −25°C / high humidity | Torque consistency maintained |

| Middle East | 6 months | 40–50°C / dusty | No bearing wear or heat fade |

| South America | 9 months | Mixed terrain | Consistent NVH performance |

Through data feedback loops, KASEN continuously refines its materials and design tolerances, creating a globally reliable clutch platform.

7. Packaging, Logistics, and Local Support

KASEN’s global distribution network supports regional adaptation through optimized logistics and after-sales service:

-

Shock-resistant packaging for long-distance ocean and land transport.

-

Warehouse hubs in Germany, UAE, and Mexico for regional supply.

-

Bilingual technical teams offering installation and service guidance.

-

OEM warranty support with serial-number traceability.

This infrastructure ensures that every A/C compressor clutch reaches customers in perfect condition and with localized engineering support.

KASEN’s Global Engineering Philosophy

At KASEN, global design means localized reliability.

Whether operating under tropical humidity, desert heat, or alpine cold, every A/C compressor clutch embodies Kasen’s principle of engineering precision, environmental adaptation, and long-term dependability.

To learn more about KASEN’s climate-specific clutch solutions or to request OEM cooperation, please visit the KASEN homepage or contact our global support team via the contact page.

FAQ: A/C Compressor Clutch Global Application

Q1. Does Kasen customize clutches for regional climates?

Yes. Kasen offers material and design modifications based on regional humidity, temperature, and altitude profiles.

Q2. How does Kasen test for desert or humid environments?

All A/C compressor clutch models undergo environmental chamber simulations and real-world field trials in respective regions.

Q3. Are clutches for cold climates different from standard versions?

They include specialized grease, low-resistance coils, and temperature-stable materials for cold starting reliability.

Q4. Can Kasen supply region-specific documentation or certifications?

Yes, full validation data and regional compliance reports are available upon request for OEM or aftermarket partners.