Repair and Maintenance Insights: Extending the Service Life of Automotive Air Conditioner Clutch Systems

Precision Maintenance to Maximize System Longevity

The automotive air conditioner clutch is a mechanical-electrical interface that demands precise alignment, clean engagement, and proper electrical health to maintain stable cooling performance.

Neglecting regular inspection leads to early coil burnout, bearing wear, or clutch slippage. KASEN’s maintenance framework emphasizes preventive care, helping both workshops and fleet operators extend clutch life far beyond the standard service interval.

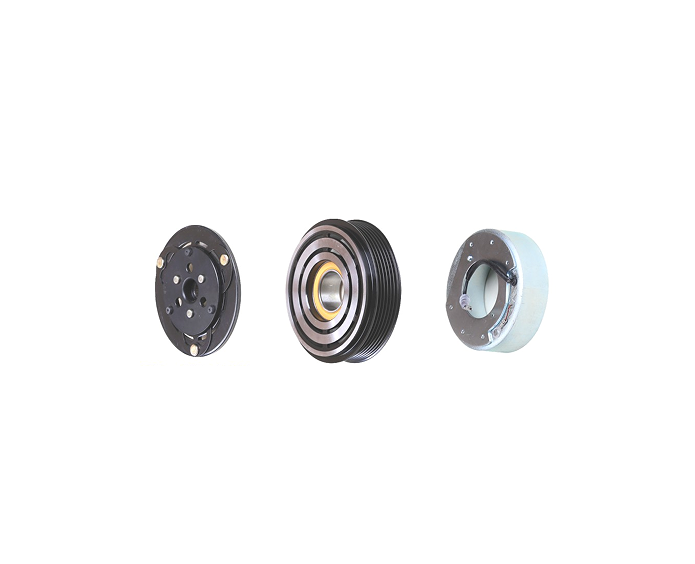

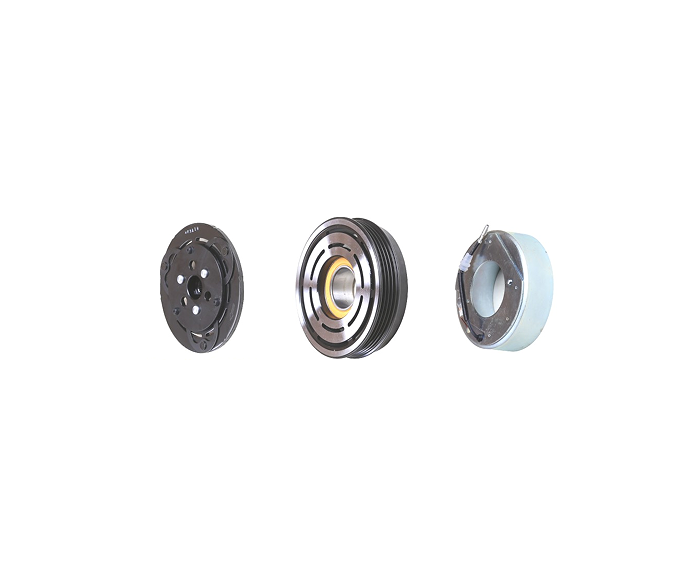

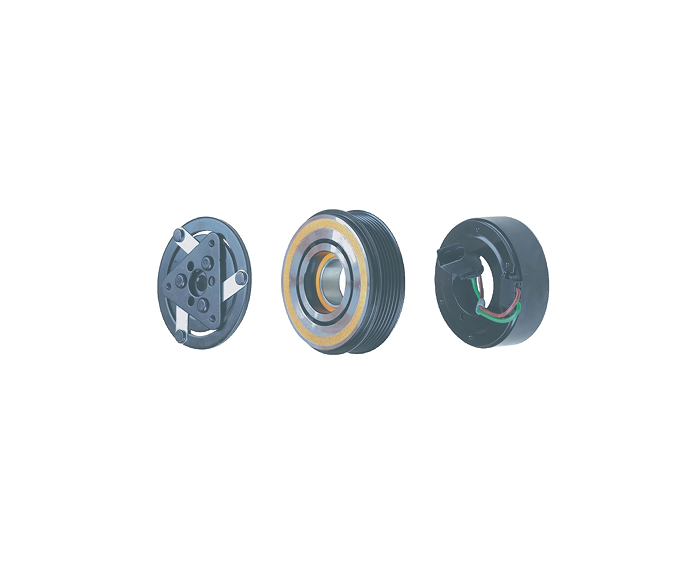

1. Understanding the Key Components Before Servicing

Before disassembly, technicians should understand how the automotive air conditioner clutch works. The system comprises:

| Component | Function | Failure Sign |

|---|---|---|

| Pulley | Transfers drive from engine belt | Noise or vibration during rotation |

| Electromagnetic Coil | Engages clutch via magnetic field | No engagement at command voltage |

| Armature Plate | Friction interface to compressor | Slip marks or discoloration |

| Bearing | Supports pulley rotation | Growling or metallic noise |

| Shim/Air Gap | Controls engagement clearance | Late or inconsistent clutch activation |

A basic pre-service inspection of these elements reduces the likelihood of incorrect reassembly and post-repair failure.

2. Correct Air Gap Adjustment for Reliable Engagement

One of the most common causes of automotive air conditioner clutch failure is improper air gap.

An excessively large gap delays engagement; too small causes friction and coil overheating.

KASEN Recommended Clearance:

-

Standard range: 0.35 mm – 0.45 mm

-

Tolerance: ±0.05 mm

-

Inspection method: Use a nonmagnetic feeler gauge at three evenly spaced points around the pulley

If adjustment is required, technicians can add or remove shims between the compressor hub and armature plate. Always rotate the clutch by hand after adjustment to confirm free movement.

3. Testing the Electromagnetic Coil and Electrical Circuit

The coil drives the clutch engagement and should be tested whenever system malfunction is suspected.

Step-by-Step Coil Inspection:

-

Resistance Measurement – Disconnect the clutch connector and measure resistance with a digital multimeter.

-

Normal value: 3.5–4.0 Ω at 20°C

-

If resistance is higher or infinite → internal coil break.

-

-

Continuity and Ground Test – Ensure the coil circuit has no ground leakage.

-

Voltage Supply Check – Confirm 12V (±0.5V) at the connector during A/C ON.

-

Magnetic Pull Test – When energized, the clutch plate should attract firmly and evenly with no chatter.

KASEN recommends checking voltage drop under load—anything below 10.5V can cause weak engagement and slip.

4. Bearing and Lubrication Inspection

Bearing wear leads to the majority of clutch noise complaints.

KASEN uses high-temperature synthetic grease and double-sealed bearings, but prolonged contamination or belt misalignment can shorten lifespan.

Maintenance Steps:

-

Rotate the pulley by hand—any roughness or grinding indicates replacement.

-

Inspect belt tension: excessive tension accelerates bearing load.

-

Avoid washing the compressor directly with water or solvent near the bearing area.

Typical Service Interval: Replace or re-grease every 100,000–120,000 km, depending on vehicle duty cycle.

5. Friction Surface Cleaning and Plate Inspection

Clutch slippage results in glazing or discoloration on the friction plate.

Before replacement, surface condition can often be restored if wear depth is within 0.05 mm.

Refurbishing Procedure:

-

Lightly sand the friction surface using 400-grit abrasive paper in a cross-hatch pattern.

-

Clean debris using non-residue brake cleaner.

-

Check plate flatness (≤0.02 mm deviation) with a precision gauge.

-

Replace immediately if the surface shows cracks or heat spots larger than 3 mm.

After cleaning, reassemble and test torque under load to ensure stable engagement.

6. Common Faults and Diagnostic Indicators

The following table summarizes typical faults and troubleshooting approaches for automotive air conditioner clutch systems:

| Symptom | Possible Cause | Corrective Action |

|---|---|---|

| No clutch engagement | Open coil circuit | Measure resistance, replace coil |

| Burning smell during A/C ON | Coil overheating from low voltage | Inspect relay and wiring |

| Squealing noise | Worn bearing or glazed friction | Replace bearing, resurface plate |

| Vibration at idle | Belt misalignment or bent pulley | Realign pulley, replace if needed |

| Intermittent A/C cooling | Air gap too wide | Adjust to factory clearance |

Preventive inspections every 20,000 km can preempt most of these issues.

7. Installation Practices to Prevent Early Failure

Incorrect reinstallation is a common cause of recurring clutch problems.

KASEN’s engineering team provides key recommendations:

-

Always use a torque wrench—tighten center bolt to 10–12 N·m.

-

Ensure the compressor shaft and pulley are perfectly aligned.

-

Replace all shims with genuine thickness options.

-

Verify coil ground integrity before final assembly.

-

After reassembly, idle the engine with A/C ON for 10 minutes to confirm smooth engagement and temperature stability.

Proper installation restores OEM-level performance and eliminates early field failures.

KASEN’s Commitment to Aftermarket Support

KASEN not only engineers durable clutch systems but also provides global after-sales and training support.

Each automotive air conditioner clutch includes traceable QR-coded batch data and detailed installation instructions.

Authorized service partners can access coil specifications, torque data, and diagnostic charts through KASEN’s technical portal.

For OEMs, distributors, and repair centers seeking reliability and technical consistency, visit the KASEN homepage or contact our service specialists via the contact page.

FAQ: Automotive Air Conditioner Clutch Maintenance

Q1. How often should the clutch air gap be inspected?

Every 40,000 km or during compressor service.

Q2. What voltage range ensures proper coil engagement?

Between 10.5–14.5V under load, depending on system type.

Q3. Can a burnt clutch coil be rewound?

It’s not recommended—replace with an OEM coil for consistent magnetic performance.

Q4. How to prevent early bearing failure?

Ensure correct belt tension and avoid exposure to moisture or dust ingress.