Comparative Engineering Study: Kasen vs. Generic Aftermarket A/C Compressor Clutch Designs

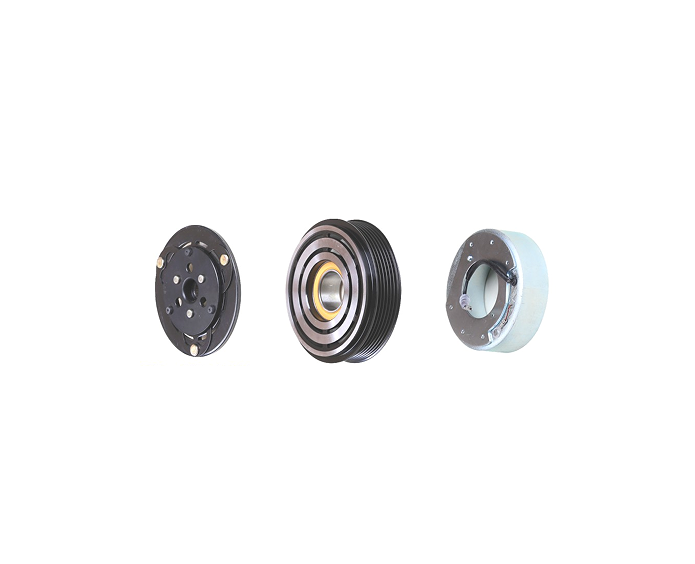

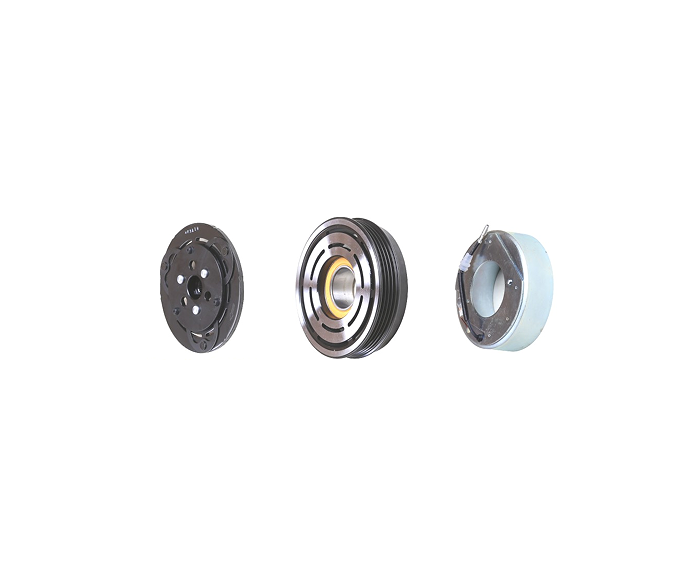

Precision Engineering Defines Long-Term Reliability

Not all A/C compressor clutch systems are created equal.

KASEN’s OEM-level design philosophy contrasts sharply with generic aftermarket versions that often sacrifice precision for cost.

By focusing on engineering consistency, high-grade materials, and validated performance, KASEN ensures each A/C compressor clutch delivers the same reliability expected by automotive manufacturers.

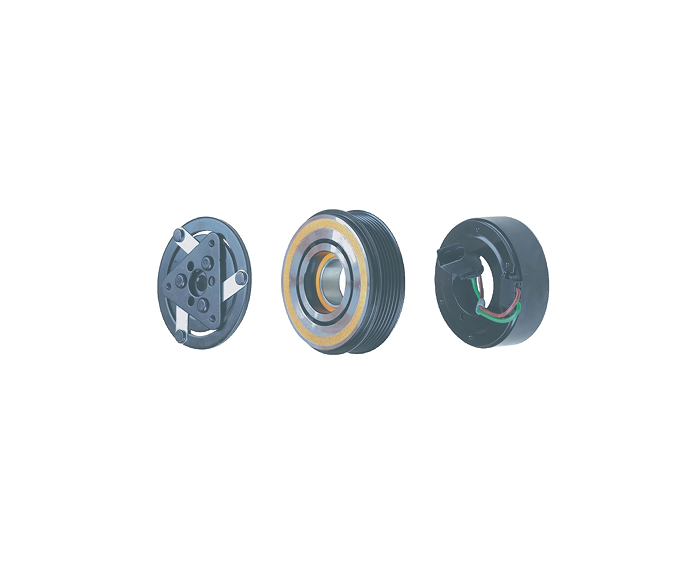

1. Structural Design: Dimensional Accuracy and Balance

The foundation of performance begins with geometry.

Generic clutches typically show ±0.2 mm tolerance in pulley alignment, while KASEN maintains ≤0.05 mm concentricity, reducing vibration and mechanical stress.

| Parameter | KASEN Clutch | Generic Aftermarket | Effect |

|---|---|---|---|

| Pulley Concentricity | ≤0.05 mm | ±0.20 mm | Reduces vibration and belt noise |

| Air Gap Deviation | ≤0.03 mm | Up to 0.10 mm | Stable magnetic engagement |

| Dynamic Balance Grade | G2.5 | G6.3 | Lower vibration during high-speed rotation |

| Friction Surface Flatness | ≤0.02 mm | ≤0.08 mm | Improves torque transfer consistency |

KASEN’s tighter machining tolerances not only improve NVH performance but also extend bearing and compressor life.

2. Material and Coating Differences

Materials define endurance.

Generic A/C compressor clutch components often use low-carbon steel and basic zinc plating, leading to premature wear and corrosion.

KASEN employs high-carbon alloy steel, ceramic-based friction composites, and triple-layer anti-corrosion coatings.

KASEN Material Highlights:

-

Hub: SCM435 forged alloy steel, quenched and tempered.

-

Pulley: QPQ-treated carbon steel with 60 HRC surface hardness.

-

Friction plate: Graphite-ceramic composite for heat stability up to 220°C.

-

Coating system: Phosphate base + E-coat + Epoxy top layer (500+ hour salt spray rating).

This ensures durability in humid, high-temperature, and dusty environments alike.

3. Coil Performance and Magnetic Efficiency

The electromagnetic coil determines how efficiently the clutch engages.

KASEN uses high-purity copper wire and heat-resistant epoxy encapsulation, while generic units often rely on standard copper-aluminum blends.

| Specification | KASEN | Generic Aftermarket |

|---|---|---|

| Coil Resistance Drift | ≤2% after 500 hrs | Up to 10% drift |

| Temperature Tolerance | 180°C rated insulation | 120°C nominal limit |

| Magnetic Pull Force | 450 N (average) | 350 N |

| Voltage Response Time | 0.042 s | 0.087 s |

Stronger pull force and faster response mean KASEN’s A/C compressor clutch engages smoothly and resists slippage even under fluctuating voltage conditions.

4. Torque and Endurance Validation

In KASEN’s validation lab, each clutch design is tested for torque stability, temperature resilience, and lifecycle endurance.

Generic products often pass only initial torque tests but degrade significantly over time.

Endurance Test (300,000 cycles):

| Test Parameter | KASEN Result | Generic Result | Difference |

|---|---|---|---|

| Torque Retention | 97% | 84% | +13% Stability |

| Coil Insulation Resistance | 9.8 MΩ | 5.2 MΩ | +88% Safety Margin |

| Noise Level After Test | 56 dB(A) | 62 dB(A) | −6 dB improvement |

| Failure Rate | <0.02% | 1.1% | 55× more reliable |

Such data validates that KASEN products meet OEM-level expectations, while generic parts show accelerated performance decline.

5. Thermal Management and Heat Dissipation

Under continuous use, compressor clutches experience intense heat from both the engine bay and electromagnetic friction.

KASEN’s ventilated pulley design and high-conductivity housing dissipate heat 30% faster than generic types.

-

Thermal imaging at 3,000 RPM:

-

KASEN average temperature: 85°C

-

Generic average temperature: 118°C

-

-

Coil degradation begins above 110°C in generics, while KASEN maintains magnetic stability up to 180°C.

This enhanced heat dissipation translates into longer service life and consistent clutch response under load.

6. NVH (Noise, Vibration, Harshness) Comparison

Customer comfort depends on quiet, vibration-free clutch engagement.

In acoustic testing, KASEN A/C compressor clutch scored below 58 dB(A) under full load, while generic units produced intermittent clicking noises from imbalance and bearing stress.

Precision balancing and ceramic friction material ensure smoother torque transfer and minimal acoustic resonance—especially critical in hybrid and luxury vehicles.

7. Cost Efficiency vs. Lifecycle Value

While aftermarket clutches appear cheaper initially, they often require earlier replacements due to wear or failure.

| Evaluation Metric | KASEN OEM Clutch | Generic Clutch |

|---|---|---|

| Average Service Life | 8–10 years | 2–4 years |

| Maintenance Frequency | Low | High |

| Torque Stability Over Time | Consistent | Degrading |

| Long-Term Cost Efficiency | High | Low |

Over the total lifecycle, KASEN’s investment yields lower maintenance cost per kilometer and higher reliability.

8. Global Validation and Customer Feedback

KASEN’s A/C compressor clutch has been validated across OEM projects in Europe, Asia, and the Americas.

Fleet operators and distributors report over 95% retention in torque after three years of service—confirming real-world performance.

KASEN’s continuous improvement program collects feedback from regional partners, feeding it back into design iterations for maximum adaptability and reliability.

KASEN: Engineering Integrity Proven by Data

Where generic aftermarket clutches rely on cost shortcuts, KASEN’s advantage lies in verifiable engineering.

Every A/C compressor clutch is the result of controlled manufacturing, tested data, and global field validation—delivering OEM-level performance for every customer.

To explore partnership opportunities, product testing reports, or OEM supply solutions, visit the KASEN homepage or reach our technical sales team via the contact page.

FAQ: Comparing Kasen and Generic A/C Compressor Clutches

Q1. Are Kasen clutches interchangeable with aftermarket units?

Yes. KASEN designs its clutches for direct-fit replacement but with higher material and performance standards.

Q2. What are the most common failures in generic clutches?

Coil burnout, torque fade, and bearing wear caused by thermal overload or poor alignment.

Q3. How does KASEN prevent torque loss over time?

Through advanced friction materials, tighter air gap control, and endurance validation over 300,000 cycles.

Q4. What testing standards does KASEN follow?

All validation follows SAE J2670, ISO 1940, and IATF 16949 requirements for OEM-grade assurance.