A Component at the Crossroads of Comfort and Efficiency

The auto air conditioning compressor clutch engages and disengages the compressor to regulate refrigerant flow. This may sound straightforward, but in reality it’s a critical link in the chain that determines cabin comfort, fuel efficiency, and component longevity.

Market pressures are intensifying: global fuel economy regulations, EV range anxiety, climate diversity, and rising expectations for comfort are pushing clutch technology into new territory. According to a 2023 report by MarketsandMarkets, the global automotive air conditioning market is projected to grow at a CAGR of 5.8% through 2030, with OEMs demanding higher efficiency and lower NVH solutions.

Real-World Pain Points — and How to Solve Them

1. Thermal Stress in Extreme Climates

In Middle Eastern and tropical markets, AC systems operate under high thermal loads for extended periods. Standard clutches can overheat, leading to coil degradation and premature failure.

Solution:

-

Use high-temperature coil insulation rated above 180°C.

-

Implement heat-dissipating pulley designs to maintain operational stability.

-

Test under simulated “worst case” duty cycles, including peak summer load.

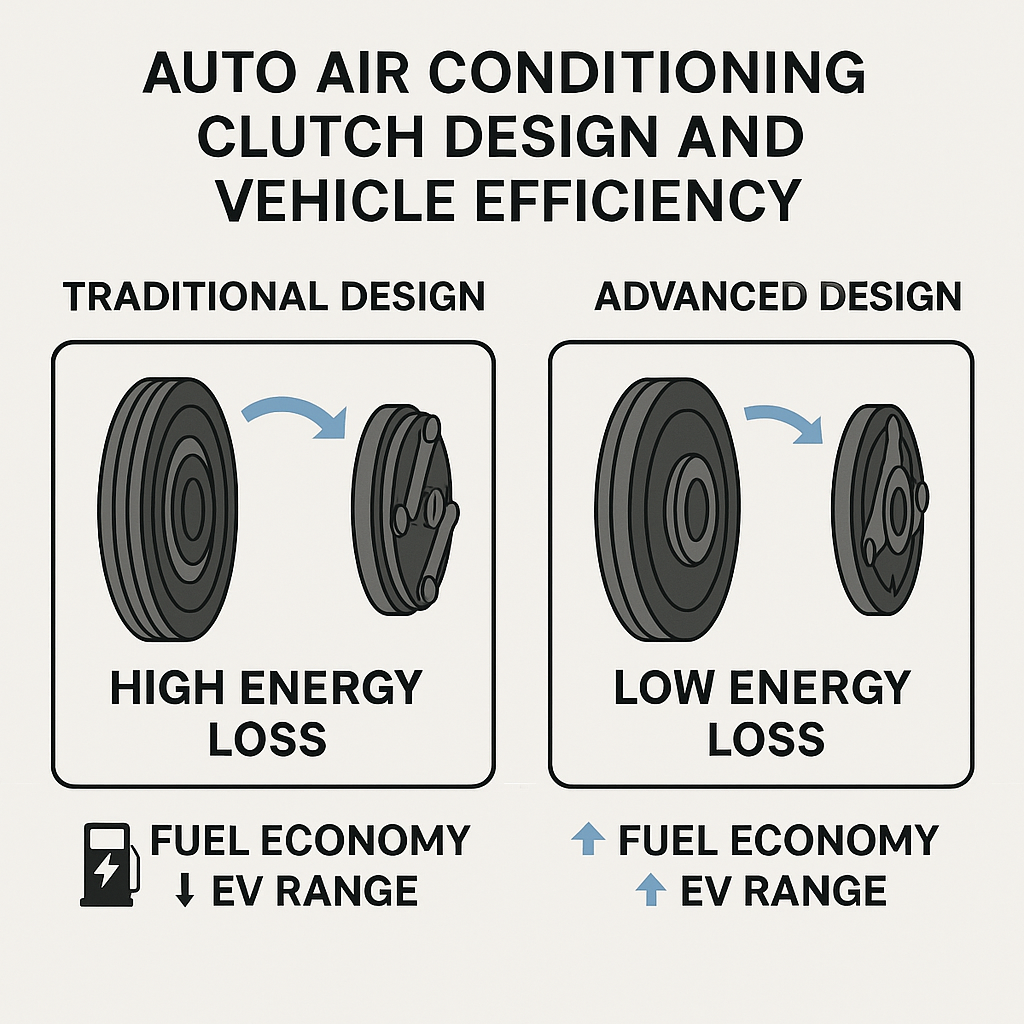

2. Energy Efficiency in Electric Vehicles

In EVs, every watt counts. An inefficient clutch increases rolling resistance and shortens driving range.

Solution:

-

Design low-drag pulley bearings to minimize idle load.

-

Integrate with smart ECU logic to engage only when necessary.

-

Use lightweight materials to reduce rotational inertia.

3. NVH Expectations in Premium Models

Luxury vehicle buyers expect quiet, seamless operation. A harsh engagement or audible click is unacceptable.

Solution:

-

Dynamic balancing to ISO 1940 standards to reduce vibration.

-

Fine-tuned engagement force profiles for smooth clutch action.

-

High-precision machining for uniform magnetic gap and torque transfer.

4. Durability in Continuous-Use Fleets

Logistics and public transport fleets run AC systems for thousands of hours per year, often in dusty or polluted environments.

Solution:

-

Reinforced bearing systems with multi-lip seals.

-

Corrosion-protected housings to withstand road salt and humidity.

-

Friction materials with wear rates tested for >100,000 engagement cycles.

Engineering Design Principles

To meet these demands, modern clutch design integrates:

-

Material Innovation – Heat-treated alloy steels, advanced composites for friction plates, corrosion-resistant coatings.

-

Precision Manufacturing – CAD/CAM machining with tolerances within ±0.01 mm, FEA simulation for load validation.

-

Performance Testing – Torque endurance tests exceeding OEM minimums by 20%, NVH validation in anechoic chambers, high-temp and humidity cycling.

-

Global Compliance – ISO 9001 for quality, CE/ROHS for market acceptance.

Actionable Selection Guidance

-

Match Torque to Application – Overspec for high-load climates, optimize for efficiency in EVs.

-

Adapt to Environment – Select corrosion-resistant and sealed units for coastal or dusty markets.

-

Prioritize NVH – For premium and urban models, choose dynamically balanced designs.

-

Plan for Maintenance – In fleets, choose modular clutches for rapid replacement and lower service downtime.

Customization Advantages and Technical Support

-

Application-Specific Engineering

Each auto air conditioning compressor clutch is designed based on the target vehicle’s operating environment, cooling load, and control system. This ensures optimal torque capacity, energy efficiency, and NVH performance without unnecessary overengineering. -

Flexible OEM Customization

From pulley profiles and coil voltages to friction materials and magnetic gap settings, every parameter can be adjusted to match the precise requirements of different platforms—whether for compact passenger cars, heavy-duty trucks, or electric vehicles. -

Material and Component Upgrades

Options for high-temperature coil insulation, corrosion-protected housings, and sealed bearing assemblies are available for vehicles operating in tropical climates, coastal areas, or dusty environments. -

Full Lifecycle Support

Our engineering team works with customers from early design consultation through mass production and post-sale support, providing technical documentation, installation guidance, and failure analysis if required. -

Rapid Prototyping and Testing

In-house prototyping capabilities and advanced test benches allow us to validate designs quickly, accelerating OEM development timelines and reducing project risks.

Engineering for the Future of Cooling

The auto air conditioning compressor clutch may be small, but its impact is industry-wide—affecting energy efficiency, passenger comfort, and operational costs. By addressing real-world pain points with tailored engineering solutions, manufacturers and operators can extend service life, improve performance, and reduce total cost of ownership.

Explore our homepage for more on our engineering approach to automotive cooling systems, or visit our contact page to discuss a project-specific clutch solution.