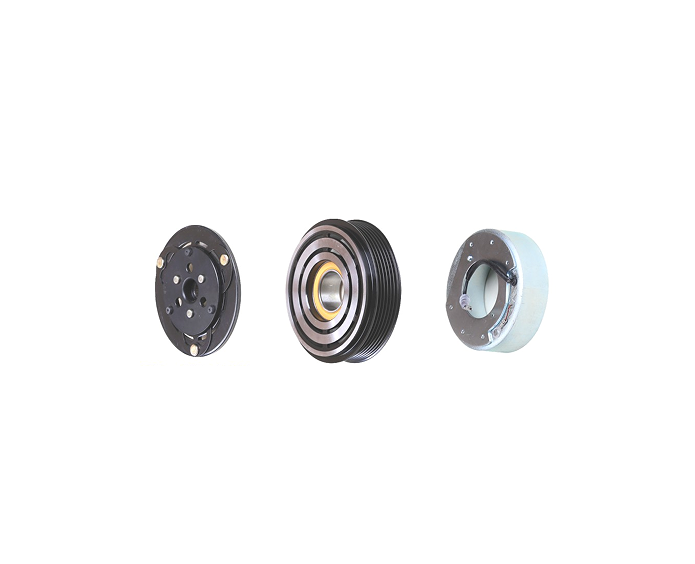

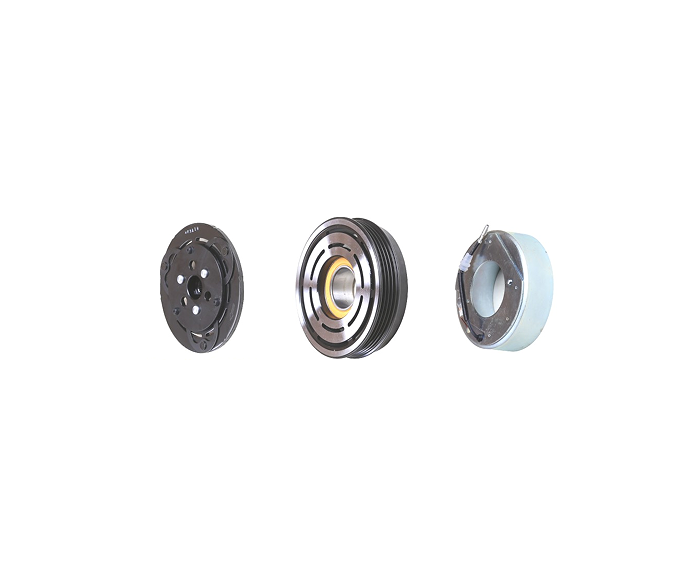

Ever wondered what makes your car’s air conditioning (AC) kick on and off? The AC compressor clutch assembly is the hidden “switch” regulating power between your engine and AC system. Let’s break down the parts in the image and explain how they keep your ride cool.

The AC compressor clutch is a magnetic mechanism acting as a bridge between your engine and the AC compressor. When you turn on the AC, the clutch engages to transfer engine power to the compressor (which pressurizes refrigerant for cooling). When the AC is off, the clutch disengages, so the compressor stops while the engine runs.

Let’s dissect the parts you see:

This large black pulley connects to your engine’s accessory belt. It spins whenever the engine runs—but on its own, it doesn’t power the compressor. Inside, a bearing lets it rotate freely when the clutch is disengaged (so the compressor stays off).

Also called a “drive plate,” this piece sits near the pulley. When activated, it clamps onto the pulley to transfer torque. It uses friction or magnetic forces to create a tight connection with the pulley when the clutch engages.

The electromagnetic coil (with the braided black wire) is the clutch’s “control center.” When electricity flows through it, it generates a magnetic field. This force pulls the pressure plate toward the pulley, locking them together. The metal mounting plate holds the coil in place and completes the electrical circuit.

AC Off: No power flows to the electromagnetic coil. The pressure plate stays separated from the pulley. The pulley spins idly (driven by the engine belt), but the compressor doesn’t run.

AC On: When you turn on the AC, electricity flows to the coil. The coil’s magnetism yanks the pressure plate against the pulley. Now, the pulley’s rotation drives the pressure plate, spinning the compressor shaft. The compressor pressurizes refrigerant, and cool air fills the cabin.

Cycling: The AC system’s sensors and control module toggle the coil’s power to maintain temperature, so the clutch engages/disengages as needed.

- Controls Cooling: Lets the engine run independently of the AC compressor, saving fuel when AC isn’t used.

- Reduces Wear: Disengaging the compressor when not in use lessens strain on engine and AC components.

- Simplifies Repairs: If your AC stops cooling, a faulty clutch (not just a bad compressor) is often to blame. Knowing these parts helps diagnose issues like a slipping clutch or dead coil.

- Warm AC air: The clutch may not engage (check if the coil has power or if the pressure plate is worn).

- Squealing when AC turns on: Likely a worn pulley bearing or loose accessory belt.

- Clutch engages then disengages: Often caused by low refrigerant pressure (the system shuts off to avoid damage).

Understanding your car’s AC compressor clutch assembly helps you spot problems early or talk to mechanics with confidence. Whether you’re DIY-ing or just curious about your vehicle’s HVAC, this guide demystifies a critical component!