Auto AC Clutch: OEM Solutions for Automotive Air Conditioning Systems

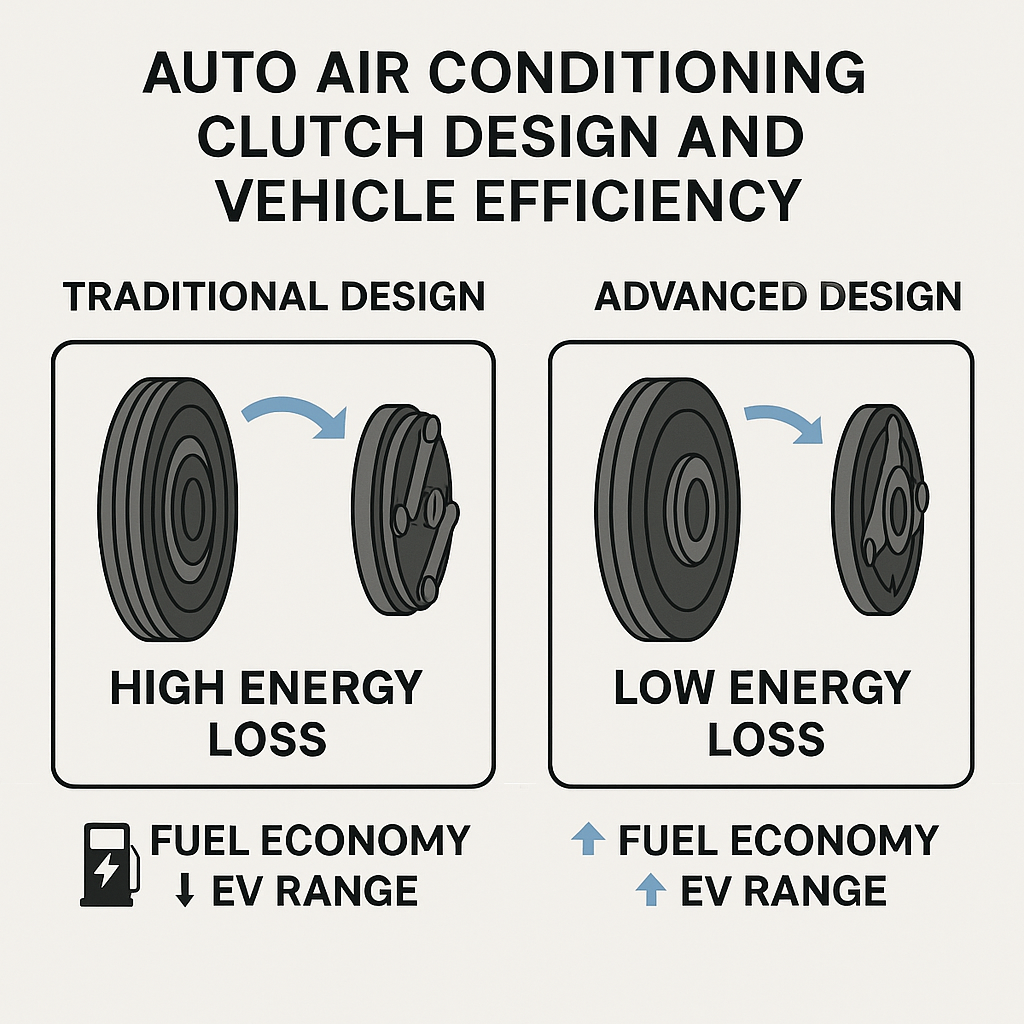

The Auto AC Clutch is the key component that engages and disengages the compressor in an automotive air conditioning system. By controlling when the compressor operates, it helps regulate cabin temperature, improve fuel efficiency, and protect the compressor from unnecessary wear. For automotive manufacturers and OEM clients, selecting or designing the right clutch is critical to achieving reliable and efficient climate control.

Role of Auto AC Clutch in Automotive Air Conditioning

In a car’s AC system, the clutch acts like a precision switch. When cooling is needed, it engages to drive the compressor, circulating refrigerant through the condenser and evaporator. When cooling demand drops, the clutch disengages, reducing engine load and energy consumption.

Its performance affects:

-

Cooling Efficiency – Faster temperature drop and stable cabin comfort.

-

Energy Management – Minimizing engine load or battery drain in EVs.

-

System Longevity – Less operating time reduces mechanical wear.

-

Noise Levels – Smooth engagement ensures a quieter ride.

OEM Customization Needs for Auto AC Clutch

In OEM applications, a “one-size-fits-all” clutch rarely meets the demands of different vehicle platforms. Factors such as engine type, cabin size, climate conditions, and regulatory standards all influence the design.

Key OEM Requirements

-

Precise Fit & Compatibility – Dimensions, pulley type, and mounting must match the compressor and vehicle layout.

-

Durability & Environmental Resistance – Able to operate under high temperatures, dust, humidity, or vibration.

-

Integration with Control Systems – Coordinated with ECU signals, variable displacement compressors, or smart AC systems.

Solutions for Different Vehicle Types

1. Passenger Cars & City Vehicles

Require compact, low-noise clutches with a balance between cooling power and fuel economy.

2. SUVs & Crossovers

Larger cabin volumes need stronger torque capacity and stable operation during higher cooling loads.

3. Luxury Vehicles

Prioritize ultra-quiet operation and seamless temperature control for passenger comfort.

4. Electric Vehicles (EVs)

Require energy-efficient clutches to minimize battery consumption while maintaining effective cooling.

5. Commercial & Heavy-Duty Vehicles

Need robust, high-durability clutches capable of long hours of operation in challenging environments.

Technical & Quality Advantages

-

Specialization in Automotive Air Conditioning Components

With years of focus on automotive AC compressor clutches, our engineering team has developed deep expertise in matching clutch design to specific vehicle requirements, from compact sedans to heavy-duty trucks. This specialization means we understand the nuances of torque demand, thermal management, and NVH (Noise, Vibration, Harshness) control better than general parts manufacturers. -

OEM-Centric Design & Co-Development Capability

We provide full OEM co-design services, working closely with automotive manufacturers from the early stages of vehicle development. This allows integration of custom coil parameters, pulley configurations, and friction materials that perfectly match each model’s AC system, electrical characteristics, and performance goals. -

Material Innovation & Durability

Our clutches use heat-resistant alloy steel for friction surfaces, reinforced bearing systems for extended life, and corrosion-protected housings for harsh environments. Advanced heat treatment and surface finishing ensure consistent performance even in tropical climates, high-altitude regions, or dusty off-road conditions. -

Rigorous Quality Control & Global Certification

Every unit undergoes 100% dynamic balance checks, torque load verification, and endurance testing that simulates years of real-world use. Our manufacturing facilities are ISO 9001 certified, and products meet CE and ROHS compliance, ensuring they are ready for global distribution.

Selection & Maintenance Solutions

-

Selection Solutions for OEM and Aftermarket

-

Match to Compressor and Vehicle Specs – Always select a clutch with exact pulley groove count, diameter, and mounting pattern to ensure seamless fit with the compressor model and engine bay layout.

-

Design for Climate & Duty Cycle – For vehicles in tropical climates or with high AC usage (e.g., taxis, delivery fleets), choose clutches rated for continuous high-load operation with reinforced bearings and upgraded coil insulation.

-

Torque & Electrical Compatibility – Ensure the clutch torque rating matches the compressor load requirements, and that coil voltage aligns with the vehicle’s electrical system to avoid underperformance or overheating.

-

OEM Co-Development – In vehicle development stages, integrate clutch design into the AC system architecture early. This allows custom coil resistance, magnetic field strength, and friction material selection to meet brand-specific performance targets.

-

-

Maintenance Solutions to Extend Service Life

-

Belt & Pulley Health – Inspect drive belts for tension and wear. An overtightened belt accelerates bearing wear; a loose belt causes slippage and heat buildup.

-

System Cleanliness – Keep condenser fins and airflow paths clean to reduce compressor load, which in turn lowers clutch stress.

-

Refrigerant & Lubrication Management – Maintain correct refrigerant charge and compressor oil level. Low refrigerant forces the compressor to work harder, raising clutch engagement temperature.

-

Early Fault Intervention – Address symptoms like delayed engagement, metallic noise, or reduced cooling immediately by checking coil resistance, air gap, and bearing condition.

-

Seasonal Operation – Even in winter, run the AC system briefly every few weeks to keep the clutch and compressor lubricated, preventing rust and seal deterioration.

-

Ensuring Long-Term Reliability with the Right Auto AC Clutch

The Auto AC Clutch is more than just a mechanical part—it’s a performance-critical component that determines the efficiency, comfort, and reliability of a vehicle’s climate control system. OEM-customized solutions ensure each vehicle type gets the exact performance it needs.

Visit our homepage to explore our full range of automotive air conditioning components, or go to our contact page to discuss your OEM requirements with our technical team.