From Hidden Energy Drain to Efficiency Driver: The Clutch’s New Role in HVAC Systems

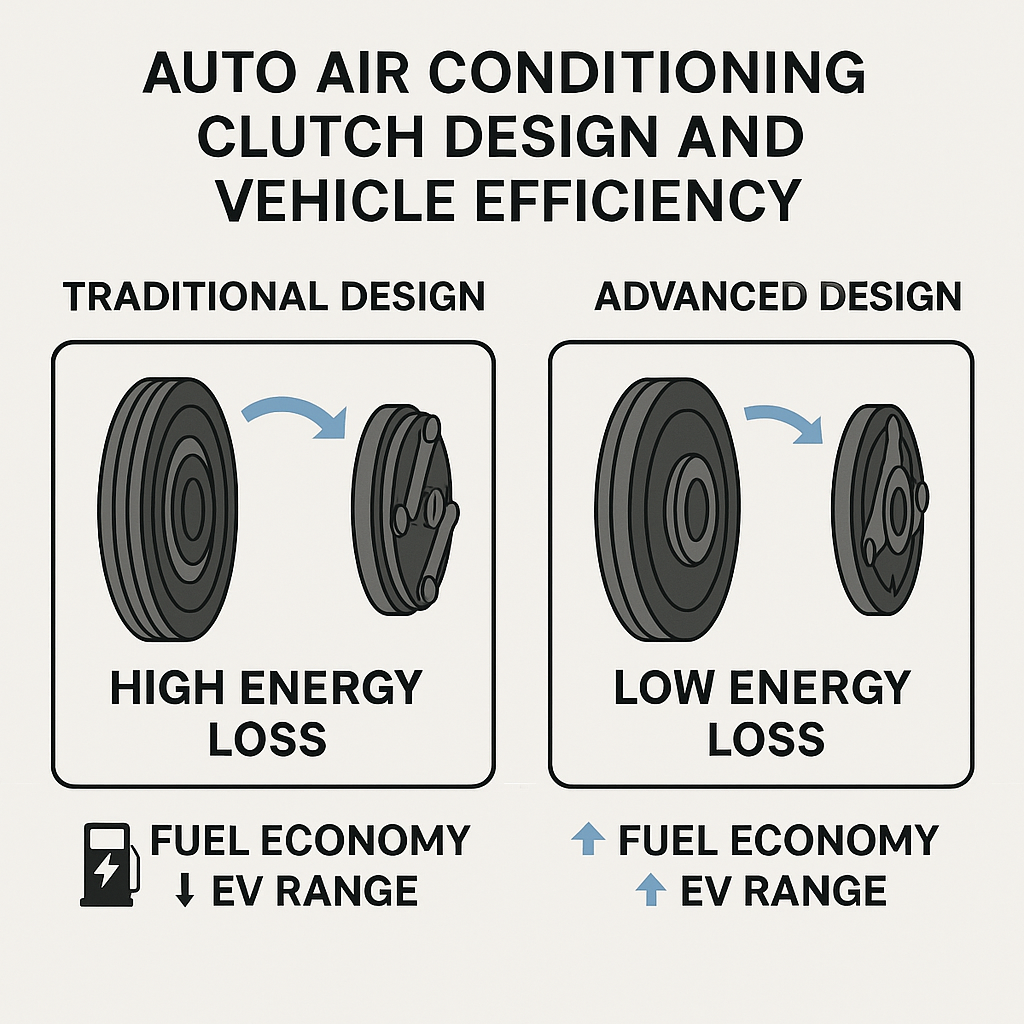

The auto air conditioning clutch controls when the compressor engages, directly impacting the energy consumption of a vehicle’s HVAC system. In internal combustion engines (ICE), unnecessary compressor engagement translates into wasted fuel; in electric vehicles (EVs), it shortens driving range. An advanced clutch design can minimize these losses, optimize cooling performance, and meet increasingly strict global efficiency regulations.

Why the Auto Air Conditioning Clutch Is Central to Modern Fuel and Range Gains

A conventional AC clutch generates drag even when disengaged—friction in the bearing, resistance from the pulley, and inertia during acceleration all consume energy. Studies show that HVAC parasitic load can reduce EV range by up to 10% and ICE fuel economy by 0.3–0.5 L/100 km.

Engineering Opportunity: By reducing idle drag, optimizing mass distribution, and improving magnetic engagement efficiency, these losses can be cut dramatically without compromising cooling capacity.

Cutting Parasitic Drag: The First Step to Better Fuel Economy and EV Range

-

Low-Drag Bearing Systems – Precision low-friction bearings reduce rolling resistance when the clutch is disengaged, helping EVs gain extra range and ICE vehicles improve mileage.

-

Lightweight Pulley Construction – Aluminum alloy or composite pulleys lower rotational inertia, reducing load on the powertrain during acceleration.

-

Optimized Magnetic Circuit – Fine-tuned coil and magnetic path geometry enable faster engagement with less electrical draw.

-

Dynamic Balancing for NVH – Precision balancing minimizes vibration and noise, improving both comfort and component life.

-

Environmental Protection – Targeted coatings and seals maintain performance in coastal, desert, or cold climates.

How OEMs and Fleets Achieved Measurable HVAC Efficiency Improvements

-

EV Application: A European compact EV platform gained 3–4% range improvement after adopting Kasen’s low-drag clutch and ECU-integrated control logic.

-

Urban Passenger Car: A hybrid sedan reduced HVAC-related fuel consumption by 0.4 L/100 km with a lightweight, dynamically balanced pulley system.

-

Commercial Fleet: A Southeast Asian delivery fleet extended service intervals by 30%, cutting downtime and operational fuel costs.

Tailored Clutch Designs That Match Platform Requirements and Market Demands

Kasen’s engineering process starts with real duty cycle data—climate, compressor maps, NVH targets—then applies:

-

Pulley profile/material customization for belt drive compatibility

-

Coil voltage and magnetic force tuning for fast, efficient engagement

-

Friction material selection for torque stability and longevity

-

Seal and coating options for specific environmental challenges

Integrating Clutch Design into a Holistic Vehicle Energy Strategy

An advanced clutch is only one piece of the HVAC efficiency puzzle. When paired with smart HVAC controls, high-efficiency compressors, and optimized thermal management, the result is a significant reduction in energy usage without compromising comfort.

Turning Vehicle Efficiency Targets into Validated HVAC Performance with Kasen

By focusing on low-drag mechanics, lightweight construction, and platform-specific tuning, Kasen transforms the auto air conditioning clutch from a standard part into a competitive advantage. For OEMs, Tier 1 suppliers, and fleet operators, this means better efficiency, fewer emissions, and lower total cost of ownership.

Explore our homepage or start a tailored clutch design discussion through our contact page.